A Guide to Understanding Acoustic Test Results

In this guide, we will explain in detail the way Acoustic Test results are displayed, what they mean and our guidance for common errors in construction leading to causes of failures in Sound Testing.

Acoustic Test Results are a good indication for potential improvements you could expect but are not a solid confirmation of what you will achieve.

Every property will behave differently, even if you consider them to be built and laid out the same.

Brief Background on Acoustic Testing

Acoustic Testing is often associated with members of the Institute of Acoustics (IOA) in the UK, which in a professional body for those working in acoustics, noise and vibration (ANV). A member of the IOA is often graded via membership and that company or persons contribution to the field of ANV.

An excerpt from IOA;

“The Institute has some 3000 members from a rich diversity of backgrounds, with engineers, scientists, educators, lawyers, occupational hygienists, architects and environmental health officers among their number. This multidisciplinary culture provides a productive environment for cross-fertilisation of ideas and initiatives. The range of interests of members within the world of acoustics is equally wide, embracing such aspects as aerodynamics, architectural acoustics, building acoustics, electroacoustics, engineering dynamics, noise and vibration, hearing, speech, underwater acoustics, together with a variety of environmental aspects. The lively nature of the Institute is demonstrated by the breadth of its learned society programmes.”

It is good practice for those involved in Acoustic Testing to be a part of the IOA.

UKAS Accreditation is another body that provides Certification, Testing, Inspection and Calibration Services, which assesses an organisation.

An organisation with this accreditation is valuable, as they adhere to rigorous testing in the above areas. iKoustic partner with a UKAS accredited Acoustic Testing company to display our acoustic results as well as our Noise Impact Assessments and Part E Building Regulations.

An excerpt from UKAS;

“Accreditation is increasingly being recognised as a valuable tool across a wide range of Government policy areas including better regulation, good governance, fair markets and public confidence. It is already being used by Government as an effective market-led tool for delivering policy more efficiently and to help deliver on its obligations in areas as diverse as healthcare, food production, energy supply, climate change and personal safety.”

https://www.ukas.com/about/the-benefits/

How an Acoustic Test is Performed in the Field and their Results

There are two tests that are most commonly carried out, helping to survey a property between partitions for Part E Building Regulations, or the impact of noise via a new development as a Noise Impact Assessment.

Part E Building Regulations, Airborne and Impact

Part E Building Regulations is an Approved Document set by the government for minimum performance values in Airborne and/or Impact Noise (see our Science of Soundproofing for meanings behind these terms), it was first introduced in 2003, with amendments made in 2004, 2010, 2013 and 2015.

“Airborne sound insulation of a separating wall or floor B2.2 The airborne sound insulation of a separating wall or floor should be measured in accordance with BS EN ISO 140-4:1998. All measurements and calculations should be carried out using one-third octave frequency bands. Performance should be rated in terms of the weighted standardised level difference, DnT,w, and spectrum adaptation term, Ctr, in accordance with BS EN ISO 717-1:1997″

http://cms.thebuildingregulations.org.uk/document-section/annex-b-proced…

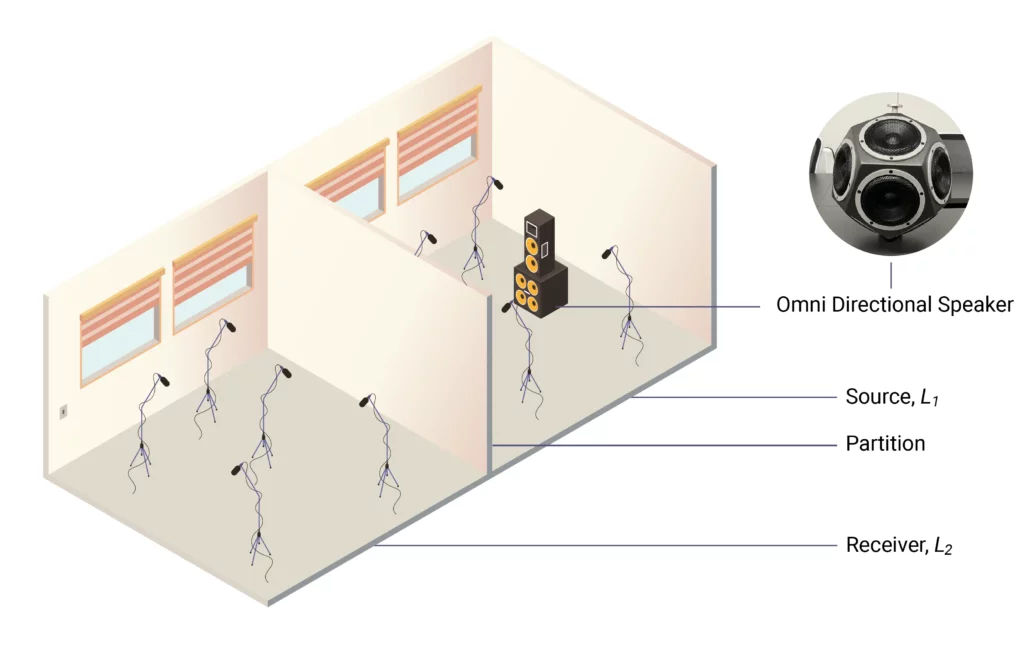

An Airborne Test is carried out with the above International Standards Organisation documents in which access is required to both properties.

- First, a background noise level is taken in the receiving room and used for corrections in the measurement (external noise issues such as traffic, weather conditions and other influential noises that may not be possible to control).

- Second, a reverberation test is carried out in which a controlled noise is played, we then immediately stop the noise and we measure the tail at the end (reverb) this is done by how long it takes for a sound to reduce below 60dB (RT60).

- Third, a controlled noise level across a broad range of frequencies is amplified through a large Dodecahedron speaker in excess of 100dB (incredibly loud). Multiple tests are taken in various locations within the room to investigate any variation in performance.

There is a source room and receiving room, and as you would expect – the source is where the sound is being carried out, and the receiving room being the recording on the other side of the partition. Results of this are referred to as a Field Measurement.

It is expressed as the following;

Weighted Standardized Level Difference with Spectrum Adaption Term (DnT,w + Ctr), DnT,w is the measured amount without correction, Ctr is the correction for low frequency interference (traffic etc) and most commonly used in the expression – you would deduct this from the 1st number.

Example; DnT,w (C;Ctr) =73 (-1;-5) dB = 68dB with the correction.

“Impact sound transmission of a separating floor B2.9 The impact sound transmission of a separating floor should be measured in accordance with BS EN ISO 140-7:1998. All measurements and calculations should be carried out using one-third-octave frequency bands. Performance should be rated in terms of the weighted standardised impact sound pressure level, L’nT,w in accordance with BS EN ISO 717-2:1997.”

http://cms.thebuildingregulations.org.uk/document-section/annex-b-proced…

An Impact Test Is carried out with the above International Standards Organisation documents in which access is required to both properties.

- First, a background noise level is taken in the receiving room and used for corrections in the measurement (external noise issues such as traffic, weather conditions and other influential noises that may not be possible to control).

- Second, a reverberation test is carried out in which a controlled noise is played, we then immediately stop the noise and we measure the tail at the end (reverb) this is done by how long it takes for a sound to reduce below 60dB (RT60).

- Third, a standardized Tapping Machine is placed, which taps the floor with a concise pattern and pressure. This, like the airborne test – is measured in various locations in both rooms to highlight any potential deviations in acoustic performance.

There is a source room and receiving room, and as you would expect – the source is where the sound is being carried out, and the receiving room being the room directly below the tapping machine. Results of this are referred to as a Field Measurement.

It is expressed as the following;

Weighted Standardized Impact Sound Pressure Level (L’nT,w), unlike airborne test results in the field, no correction is applied to this measurement.

Example; L’nT,w = 35dB

Contributing Factors to Acoustic Test Results in the Field

- Quality of Workmanship

The quality of building workmanship is very important, and often the most influential to acoustic test results. If the work carried out is of poor quality, sound proofing would need to be more robust to help alleviate these issues.

These negative contributions to poor acoustic insulation could be one or more of the following.

- Poor mortar condition between brick or block work, allowing cracks to appear

- Poor cutting and sealing of acoustic plasterboard or other acoustic materials

- Not following guidelines for product installation

- Butting soundproofing materials up against adjacent walls

- Fixing elements through a neighbouring partition wall

- Dot and Dab plasterboard as a way of ‘soundproofing’

- Lack of dense acoustic mineral wool and using a thermal roll with little density

- Packing acoustic mineral wool into a cavity, leaving your air gap bridged

You would want a professional outfit to carry out the trades work, as advice given that reflect the points above could fail a sound test (read our blog on Guidance on Passing The Sound Test)

- Low Quality Alternative Systems and Products

The quality of an acoustic system and its product components are essential, we have seen a few cases where a low-density foam looks great on paper (or in the lab) but it’s performance is misleading, and often a robust ceiling system is put in place to bolster them results.

iKoustic always look at Systems, as there are many paths in which the sound can travel, and often enough we see only a simple Acoustic Matting laid over the floorboards, where a simple result is taken without considering the system in total.

Always look at acoustic systems – we can help here!

- Correct Acoustic Specification for Your Project

It is crucial to understand a project as much as possible, by this we mean it’s construction and what you are looking to achieve, acoustically speaking.

You can read more on our Guidance to Passing the Sound Test

Laboratory Acoustic Measurements

Measurements taken of a specific acoustic material or acoustic system in a laboratory setting are meticulously controlled through every element, there are a whole range of ISO’s to follow which are here; https://www.iso.org/obp/ui/#iso:std:iso:10140:-5:ed-1:v1:en

This would only give a loose indication of what results could be expected, but you may take off up to 10dB (+) for a specific field measurement. As it is a tightly controlled environment, factors including building materials, workmanship of both the build and acoustic materials and flanking transmission are often controlled also.

“ISO 10140-2:2010 specifies a laboratory method for measuring the airborne sound insulation of building products, such as walls, floors, doors, windows, shutters, façade elements, façades, glazing, small technical elements, for instance transfer air devices, airing panels (ventilation panels), outdoor air intakes, electrical raceways, transit sealing systems and combinations, for example walls or floors with linings, suspended ceilings or floating floors.“

https://www.iso.org/standard/42088.html

It is expressed as the following;

Weighted Sound Reduction Index (Rw): a single number, characterising the airborne sound insulation of a material or building element over a range of frequencies. These can also be used to compare building elements.

“ISO 10140-3:2010 specifies laboratory methods for measuring the impact sound insulation of floor assemblies.

The test results can be used to compare the sound insulation properties of building elements, classify elements according to their sound insulation capabilities, help design building products which require certain acoustic properties and estimate the in situ performance in complete buildings.”

https://www.iso.org/standard/42089.html

It is expressed as the following;

Weighted Normalized Impact Sound Pressure Level (Ln,w) : a Laboratory measurement of the acoustic performance of a flooring partition. It is important to note that there is no flanking (indirect) transmission loss, so only the partition needs to be considered.

or

Weighted Standardized Impact Sound Pressure Level (LnT,w) : a single number used to characterize the impact sound insulation of floors, based LnT measurement.

Where to Now?

We have included some additional links below, our Library contains product data sheets, acoustic results and installation guides which will help to give some indication of acoustic system performance.