Can foam soundproof a wall?

Foam cannot soundproof a wall as it is an absorbent material used to reduce reverberation and has low mass. By absorbing sound waves, it is not blocking them, which is required for soundproofing. Foam is used to improve acoustics by increasing clarity and reducing amplification through reverberation. Foam only works for the room it is installed in, foam does not work both ways.

Sound can travel through open cell acoustic foam, meaning it doesn’t reduce the noise escaping a space. For a material to block sound it needs a high mass and acoustic foam is a light weight material. Acoustic foam is often used for studios, offices and large open spaces where echo is an issue.

Is spray foam good for soundproofing?

A spray expanding foam is not good for soundproofing as it has a low mass and sets rigid. This means sound can easily travel through the low mass material and it is unable to absorb sounds as the structure is closed. For a foam to block noise, it would need a high mass as this is difficult for sound to travel through.

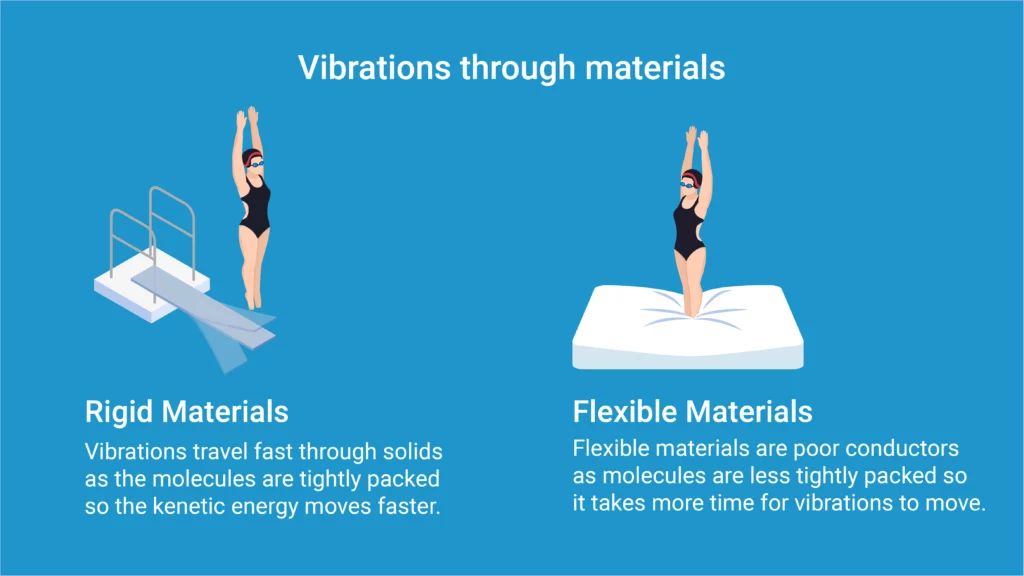

Spray foam is not a good choice for acoustically sealing gaps, either. While it would stop airflow, the low mass offers little resistance to the passage of sound and the rigid set means vibrations travel along the material. Instead, it is recommended to use an acoustic grade sealant which does not fully set. The flexible nature of this material allows it to dissipate and absorb sound energy, instead of transmitting it.

What does foam do to noise?

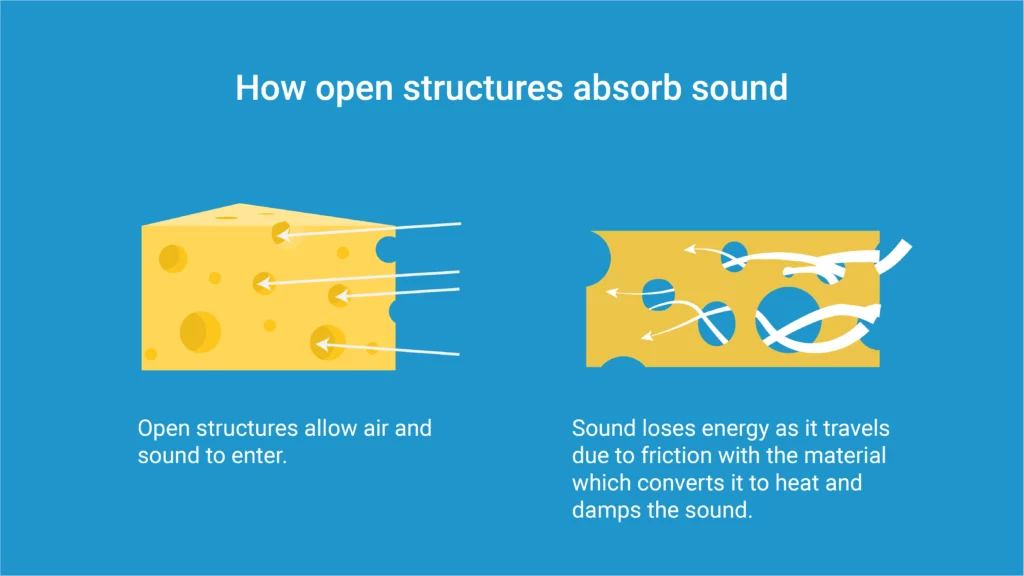

Foam panels reduce noise by absorbing the soundwaves instead of reflecting them. For foam to be acoustic (absorbent), it must have an open cell structure to allow air, and sound, to enter. Once sound enters the foam, it loses energy by minor frictional resistance. This converts kinetic sound vibrations into heat instead.

Other materials will also absorb noise, providing them have an open structure, such as loose woven fabrics and felt. Conversely, a spray foam will not help absorb sound as it sets rigid with a closed cell structure. This is why acoustic foam is technically a sound reducing foam, while not being soundproofing.

Will spray foam reduce echo?

Spray foam will not reduce echo as it is a closed cell structure. For a material to absorb sound and reduce reverberation, it needs an open structure that air can move through. Sound travels in the medium of air and can get ‘trapped’ in the material. Through friction, the sound is converted to heat energy and noise reduced. Spray foam does not allow air to flow, therefore, the material is unable to absorb noise and dissipate it.

Instead, the rigid set spray foam will allow sound to vibrate along the whole material. This is similar to a diving board; one jump causes the whole board to vibrate. Open cell foam, however, is like bouncing on a crash mat; it absorbs the vibrations but does not transmit them.

Why is closed cell foam soundproofing?

A closed cell foam has soundproofing qualities as it is a flexible material. Unlike spray foam, which sets rigid, closed cell foam can compress and then return to its original shape. This material can be used to help isolate vibrations and prevent them traveling into other materials, which may be rigid. It is often used to soundproof floors by absorbing impact from footsteps, as well as, in wall panel systems to add flex into the rigid materials.

Closed cell foam would not be a good absorber of airborne noise as the structure is not open. However, the closed cell design with the flexibility allows it to dissipate vibrations like rubber does. The material can warp with the vibrations, it is almost like a viscous solution for sound waves to try and move through.

What is an acoustic wall panel?

Acoustic wall panels are absorbent materials with an open structure which allows air and sound to enter. When sound enters it loses energy through frictional resistance with the structure and is converted to heat. Materials which are good for acoustic panels include open fibers and open cell foams.

We have a selection of open fiber acoustic panels which have a Class A rating. Class A absorbency is given to materials with a high absorbent coefficient and are the best performing options available. Acoustic panels work best when they cover around 1/3 of the hard surfaces as this will reduce enough reverberation. For music recording studios, it is best to consult an acoustic professional in order to get the design correct.