Is expanding foam soundproof?

Expanding foam is not soundproof, as the mass is too low and the structure too rigid to isolate. Soundproof materials need a high mass which will reflect airborne noises. Furthermore, expanding foam sets solid, with a closed cell structure, which means it cannot absorb sound, either. To absorb sound and reduce reverberation, a material needs an open structure through which air can flow. To help isolate sound, this closed-cell foam would need a semi-fluid set, not a solid set. Because the material is set rigidly, it is not good at isolating structures like a closed cell foam in a soundproofing panel is.

When expanding foam can improve soundproofing

Expanding foam can improve soundproofing by making a partition air tight, such as around windows. This is part of the preparatory work ahead of soundproofing and not part of the soundproofing intervention itself. For large gaps and around windows, an expanding foam may be required to fill the cavity and then finish with acoustic sealant. If you have cracks and gaps in a wall, a masonry filler should be used instead.

While expanding foam does not have acoustic properties, the ability to create an air-tight space will improve soundproofing overall. This is because sound can travel through the air, so gaps and cracks allow sound to move through with ease. Even so, due to its low mass, the foam still doesn’t provide much resistance to noise. This is why it should only be used if the space is too small for acoustic mineral wool or too large for acoustic sealant. The expanding foam should be sealed or boxed in with acoustic materials.

What is acoustic foam?

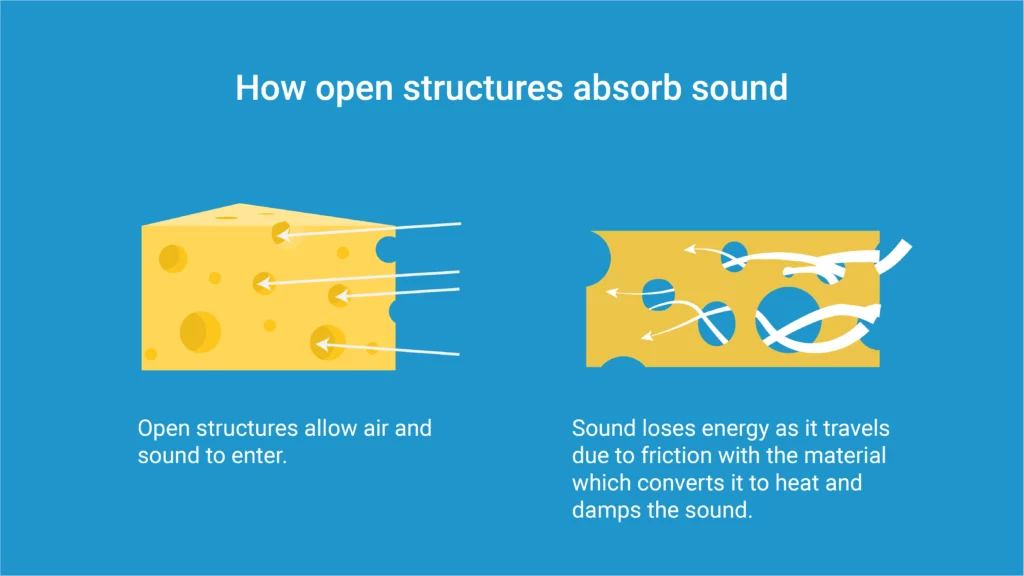

Acoustic foam is an open-cell material that absorbs sound and reduces reverberation (echo). Acoustic foam is different from expanding foam as the structure is open, which allows sound to enter and become trapped. Absorbent materials convert sound energy into other forms, like heat, through tiny frictional losses as the soundwaves touch the open cell structure.

Imagine you are a soundwave, and have to run through this Swiss-cheese-like structure. Every time you need to climb through an open cell hole, it slows you down and takes up energy. The further you go through, the slower you get. By the time you reach the end, you aren’t running and won’t bounce off the wall. This is the same for sound; the absorbent materials reduce the amount of sound that bounces from wall to wall which would cause echo.

Why is closed-cell foam soundproofing?

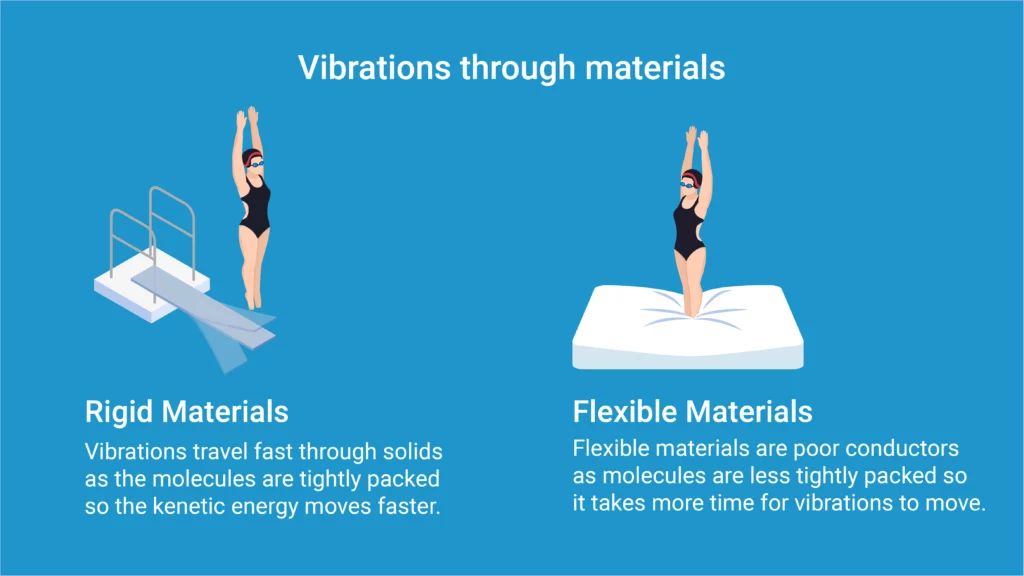

Closed-cell foam is used for soundproofing as it isolates structures. Isolation, or decoupling, is one of the three core soundproofing ‘laws’ as it reduces the transference of sound vibrations between two materials. While expanding foam is closed-cell, it doesn’t isolate materials as it’s too rigid. The flex in closed-cell soundproofing foam allows it to move and dissipate the vibrations.

Can you get soundproof expanding foam?

No, you cannot get soundproof expanding foam as it is a rigid setting, closed cell material with low mass. Instead, acoustic mineral wool should be used to fill gaps, or, for smaller areas, use acoustic sealant. Acoustic grade materials will either have a high mass to reflect sound, or, the ability to decouple structures like a shock absorber.

Expanding can help reduce the free flow of air, which is good for soundproofing. However, without materials of high mass added over this, noise will still enter.

Why is acoustic sealant good?

Acoustic sealant is good as it doesn’t fully set which allows it to isolate structures. Isolation, also known as decoupling, reduces the transference of sound from one material into another. Imagine that you have two layers of acoustic plasterboard connected together. They are both rigid, so if I push one board slightly, both will move. However, now imagine there is a layer of jelly between them. If I push one layer, the jelly will compress and transfer less pressure into the second board.

Acoustic sealant works like this and helps reduce the transmission of vibrations. It is used around the perimeter of a soundproofing partition and between the acoustic panels. By leaving a 5mm gap around the perimeter of a soundproof partition, vibrations from neighbouring structures cannot transmit across as easily.