Floor soundproofing science

We understand the science of floor soundproofing to get the best results

What does soundproofing sound like?

Turn the volume of the video down to match the noise you’re dealing with for the best results. This video is a digitally recreated noise issue that is then decreased artificially. This is designed to give you a more practical understanding of decibel reduction.

We have a whole selection of dB reduction videos over on our YouTube channel and one for every system we offer.

Bronze floor airborne

Silver floor airborne

Gold floor airborne

Floor Soundproofing Materials Explained

Acoustic Mineral Wool

Mineral wool that has a minimum density of 45kg/m3 is considered acoustic. It is available in different densities and thicknesses and is a fairly rigid material.

What is it for?

Reduce airborne noise

How does it work?

The open structure allows sound vibration to travel through and the micro-friction created between waves and fibres exhausts the sound into other forms of energy, like heat.

Where is it used?

In any open cavities between joist and stud work.

Tecsound

Tecsound is a visco-elastic membrane which comes in different weights and with the option for a self-adhesive back.

What is it for?

Reducing airborne and impact

How does it work?

Tecsound has a very mass, for reflecting airborne sound waves. The visco-elastic quality allows the material to flex and absorb impact vibrations.

Where is it used?

Tecsound is a versatile membrane used on walls, floors and ceilings.

Acoustic Sealant

As a general rule, a 2-5mm gap should be left around the perimeter of installed soundproof panels. Into this gap, the acoustic sealant is squeezed.

What is it for?

Flanking transmission

How does it work?

By leaving a gap between materials, vibrations cannot pass from one structure to the next. However, an air gap cannot be left either. Acoustic sealant doesn’t set solid and is the perfect, flexible, material to seal the gap.

Where is it used?

Walls and ceilings

Isolation Strips – Rubber Crumb

Isolation strips can be used on top of wooden joists before the floor is fitted and on stud work to act as a barrier between the wall.

What is it for?

Reducing flanking transmission

How does it work?

Made of the same rubber crumb as underlays, this non-resonant rubber reduces the transference of vibrations between flanking structures.

Where is it used?

Tops of floor joists and outside or stud work.

Mass-Loaded Vinyl (MLV)

Mass-loaded vinyl is a popular and effective soundproofing material. It’s versatile, cost effective and easy to source.

What is it for?

Reducing airborne noise

How does it work?

The high mass reflects airborne soundwaves. Using different thicknesses of MLV in one solution will reflect a wider range of frequencies.

Where is it used?

Mass loaded vinyl is a common soundproof material for floors and used in preformed wall panels. MLV can also be used as a DIY solution for doors.

Rubber Crumb Underlay

Our recycled rubber crumb underlays are made from over 90% recycled rubber tyres. These roles are effective and easy to install.

What is it for?

Reducing impact vibrations

How does it work?

Recycled rubber crumb underlays are able to compress and decompress with impact. This spreads the vibration energy and reduces transmission to other surfaces.

Where is it used?

Rubber crumb can be used as an underlay, often for concrete floors and as concrete underscreeds.

Closed-Cell Foam

The closed cell structure helps to isolate and reduce the transmission of sound vibrations from one surface to another.

What is it for?

Reducing impact vibrations

How does it work?

The closed-cell structure is able to compress and decompress which dissipates the impact energy.

Where is it used?

Closed-cell foam is excellent for floors where impact needs to be absorbed, we also use it in some preformed wall panels to mitigate vibrations between materials.

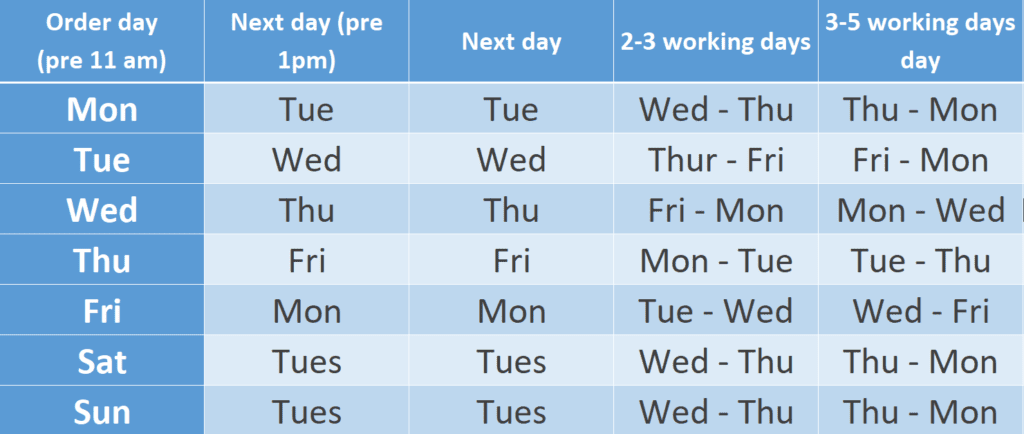

Understanding the decibel scale

Decibels are how we measure sound but due to the logarithmic nature of the Decibel scale, it isn’t the most intuitive concept to grasp. If you are interested in soundproofing the key thing to take away from this article is that reducing sound by 10dB is a perceived halving of the sound you hear. Lets take a look at some examples….

10 dB reduction

20 dB reduction

30 dB reduction

40 dB reduction

Airborne noise

Sound that uses the medium of air to travel through. Common example include talking, music and TV.

Impact noise

Sound generated by two materials coming into contact, sound vibrations travel through the materials. Common examples are footsteps and washing machines.

Flanking Transmission

When sound vibrations travel over, under or around a barrier. This could be using holes in walls made by light fixings, shelves or picture hooks. Another common example is pipe work which can vibrate with sound waves and travel between various rooms.

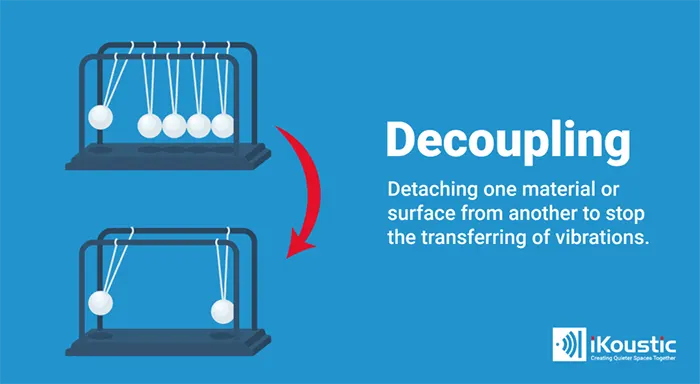

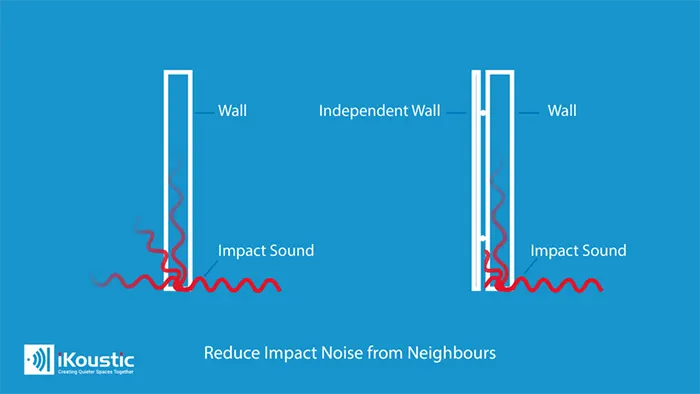

Decoupling

A method of soundproofing which reduces points of direct contact between two surfaces or places a vibration resistant material between them. Common examples are isolation clips (MuteClips), secondary stud walls and isolation strips on stud work.

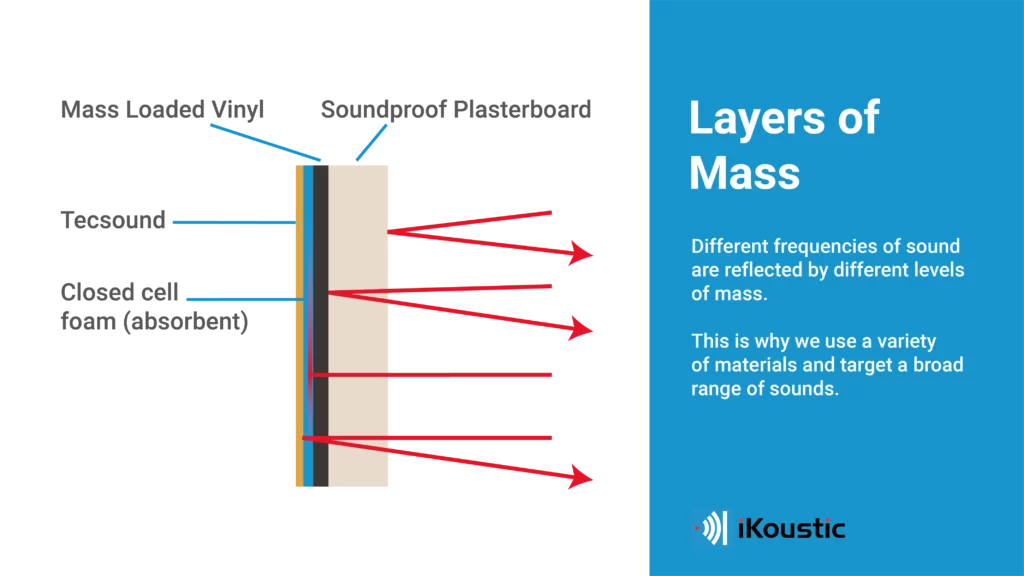

Mass addition

A method soundproofing that uses materials of high mass to reflect airborne noise within a space. This prevents sound escaping a space or entering a space.

Absorption

A method of sound control which uses materials with open structures, such as foams and loose woven fibres, to damp sound. This reduces the reflection of sound waves within a space which would lead to reverberation and the amplification of sound.

How to reduce impact noise

To reduce impact noise, which uses the structure to travel through, an ideal solution is to decouple surfaces wherever possible. This will reduce the points of contact at which vibrations are able to pass from one structure into the next.

An example of this could be a ‘floating floor’ which would make contact with the ceiling below in fewer places and reduce the volume of footsteps. Alternatively, stud walls can be rested on isolation strips which will reduce the amount of vibrations that can travel from the floor into the walls.

How to reduce airborne noise

Airborne is reduced by using materials of high mass to insulate a space. This works as the sound vibrations in the air don’t carry enough energy pass through the material, as it’s too dense t make vibrate. Instead, they are reflected away, this works to keep sound inside a space and prevent sound entering the space, too.

Materials of high mass can be added to walls, ceilings and floors and are often used to reduce ‘noisy neighbour’ disturbances.

How to reduce flanking transmission

Flanking transmission can be reduced in a multitude of ways but first and foremost the weaknesses need to be identified. These could be fixings for lights, pipe work or screws in walls. Any unavoidable weaknesses, such as pipes, can be treated as individual problems.

For example, there is soundproofing pipe wrap that can be installed to help isolate the system. For light fixings, there are sound control caps that can be fitted and likewise for electric sockets. When screws and nails are fixed to walls, it’s best to avoid drilling them further than necessary.

Conclusions

So that’s our whistle-stop tour of the soundproofing world, obviously this only scrapes the surface. If you want to learn more check out our blogs or YouTube channel.

Yes, you can install our floor soundproofing yourself if you don’t want to hire a soundproofing installer. We recommend that you’re a confident DIYer with some experience of hand tools and check to make sure you have the appropriate equipment before starting.

Installation Guides

Installation guides are available to download as a PDF from system and product pages. In these guides, you’ll find the tools required, the method for installation and some helpful diagrams. Please take a read of these before committing to a DIY install.

Installation Videos

We also have a range of installation videos to help you, these can be found on our YouTube channel.

Contact Us

If you need any extra advice when it comes to installing your floor soundproofing then you can also get in touch with us.

Where can I find a soundproofing installer?

You can find a soundproofing installer using our UK wide network. Simply fill in our form and your local soundproofing installer will be in touch.

Our reduction figures in dB denotes the improvement made to the wall, floor or ceiling. Brick walls already have a resistance of around 40dB and most sites show this figure in addition to the improvement figure obtained for the soundproofing system. This is why some sites show systems which achieve a reduction of over 60dB for a wall; it’s the resistance of the existing wall and their system combined, but we only show the figure for the system.

As every wall, floor and ceiling will resist sound differently, and the tested structure may have an especially high resistance to sound to begin with, we prefer to show the improvement figure achieved by a soundproofing system. This makes it easier for you to compare our systems and get a realistic idea of how much noise each soundproofing system will resist.

If you have any questions about data, how to read it or which soundproofing intervention you need, please get in touch with our team who will be happy to help.

dB: Decibel, which is used to measure the level of sound.

dBA: A-weighted decibels, these take into account human sensitivity to different frequencies of sound.

ΔdB: Delta decibels, which represent the change in sound level before and after the soundproofing intervention.

ΔLlin (Delta L-linear): This represents the change in sound levels on a linear scale. For example if the baseline noise level is 60dB and after soundproofing it had reduced to 50dB the ΔLlin would be 10dB.

ΔLw (Delta L-weighted): Arguably more important than the former, this represents the change in dB after soundproofing using the A-weighted scale. This therefor takes into account the human perception of sound reduction by emphasising the frequencies which the human ear is most sensitive to and de-emphasising others. In essence, ΔLw provides a more meaningful measurement of sound reduction.

Resistance to fire for our most popular system materials. Euroclass ‘A-F’ rating is for the ability of the material to catch fire, A1 and A2 rates the material as non-combustible. The ‘s’ rating, (1-3), is for the severity of smoke with s1 being the lowest. Lastly the ‘d’ rating is for droplets, d0 meaning no droplets.

Our most popular materials have the following resistance to fire:

Acoustic Plasterboard: Euroclass A2-s1, d0

60kg/m3 Acoustic Mineral Wool: Euroclass A1

100kg/m3 Acoustic Mineral Wool: Euroclass A1

Tecsound SY50: EN 13501-1:B-s2,d0

Tecsound SY70: EN 13501-1:B-s2,d0

Tecsound SY50 ALU: EN 13501-1:B-s2,d0