How to soundproof a wall (best acoustic panels and insulation) 2023

Learn how to soundproof a wall and how to stop noisy neighbours, loud music or busy roads from ruining your peace. I will explain;

- The best ways to soundproof a wall

- Cheap wall soundproofing

- How soundproofing works

- Different ways to soundproof a wall

- How to install wall soundproofing

How to Soundproof a Wall

Full system installation 2 days

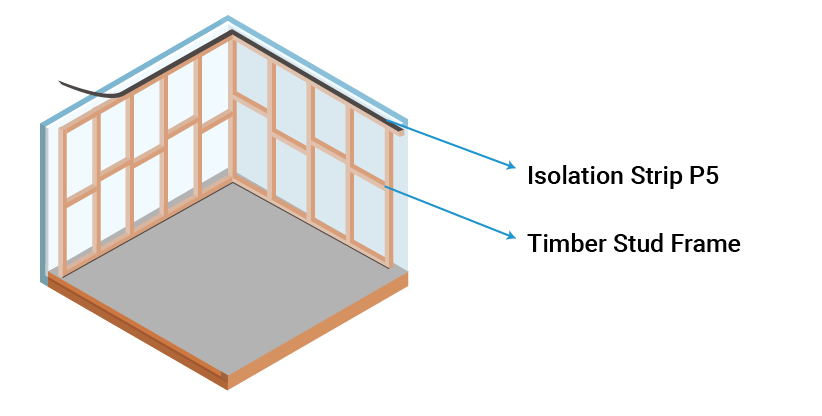

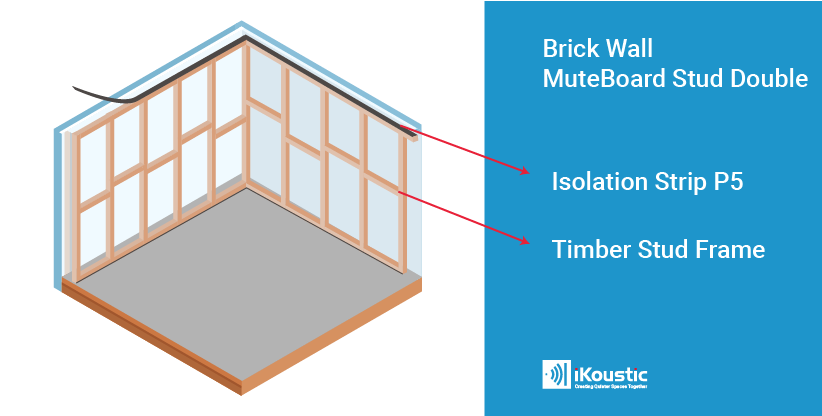

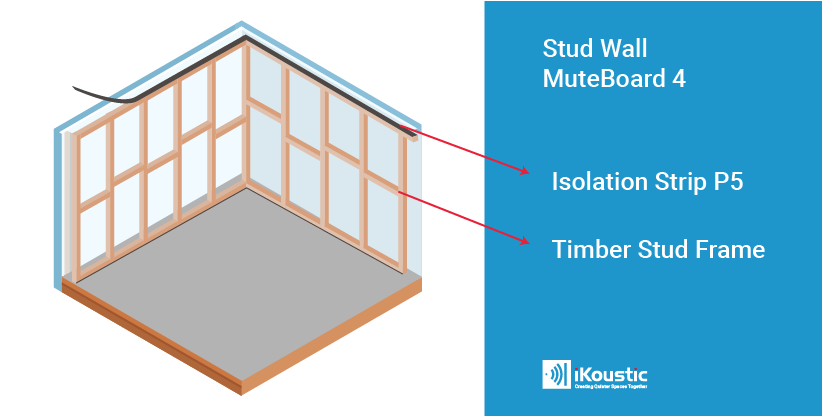

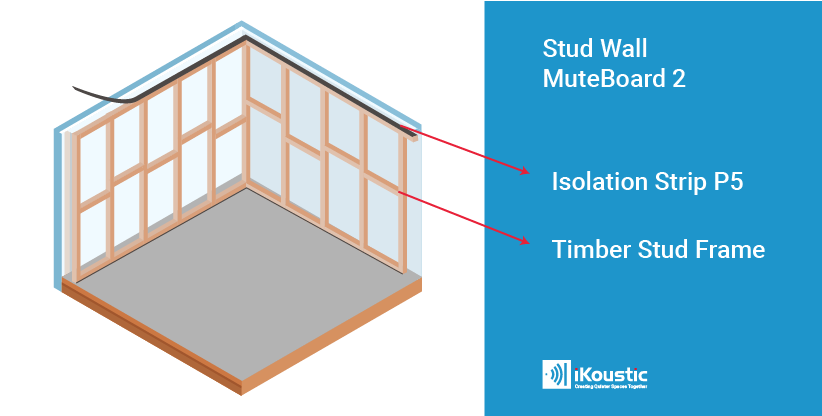

Step 1 – Install Timber Stud Frame

Measure your space and cut frame work.

Adhere Isolation strip F5 to the top and bottom of the stud wall.

Install the timber stud wall 5mm away from the original wall

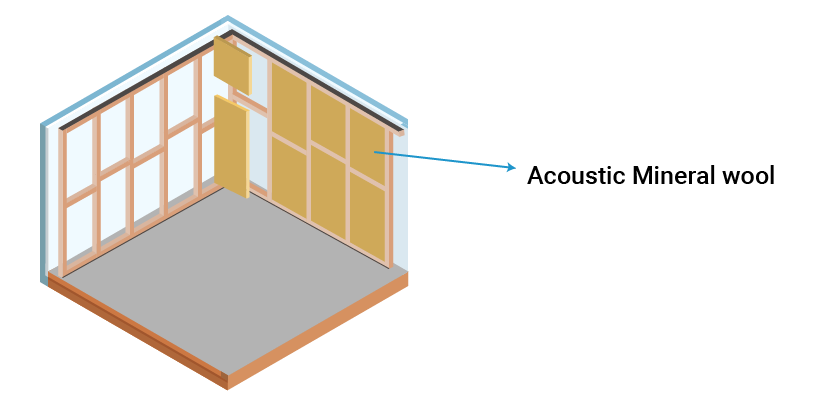

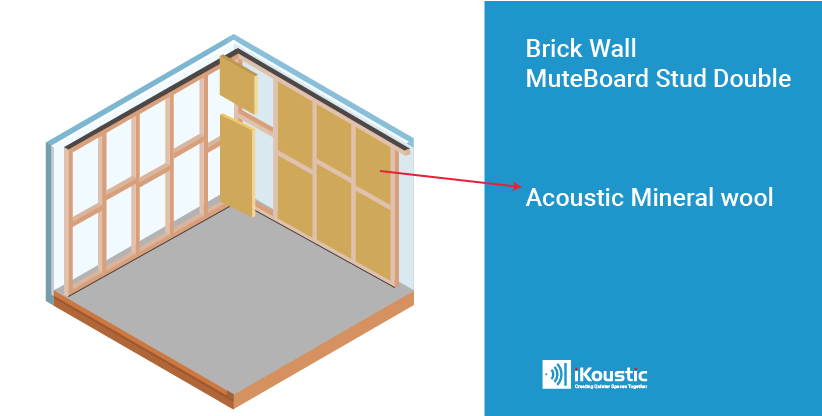

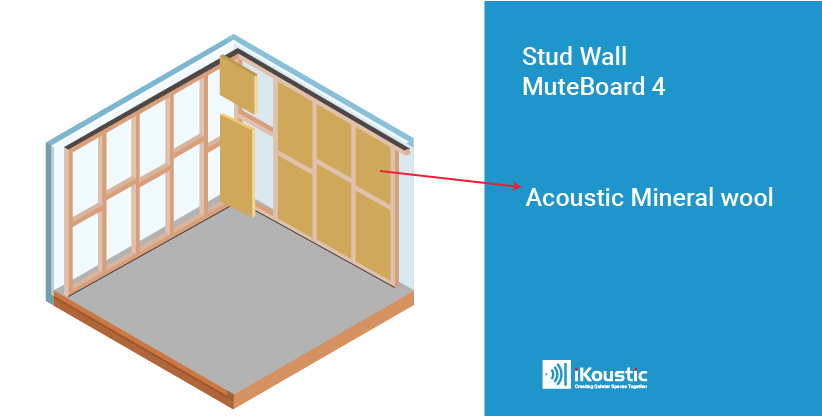

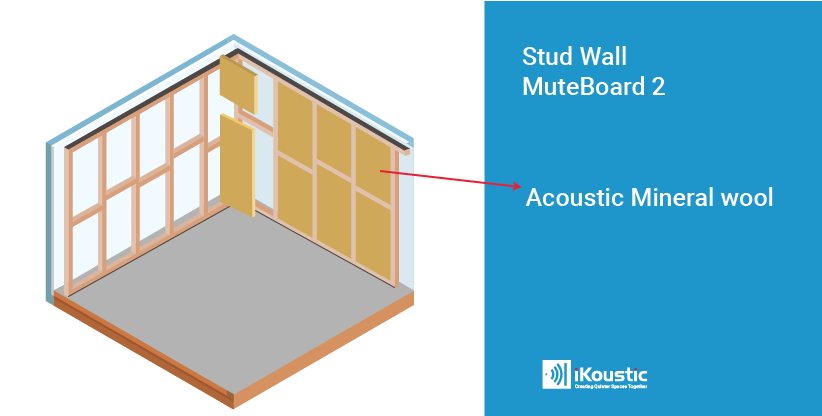

Step 2 – Install Acoustic Mineral Wool

Cut 100mm 60kg/m2 acoustic mineral wool to size.

Install acoustic mineral wool between the joists, fitting snuggly.

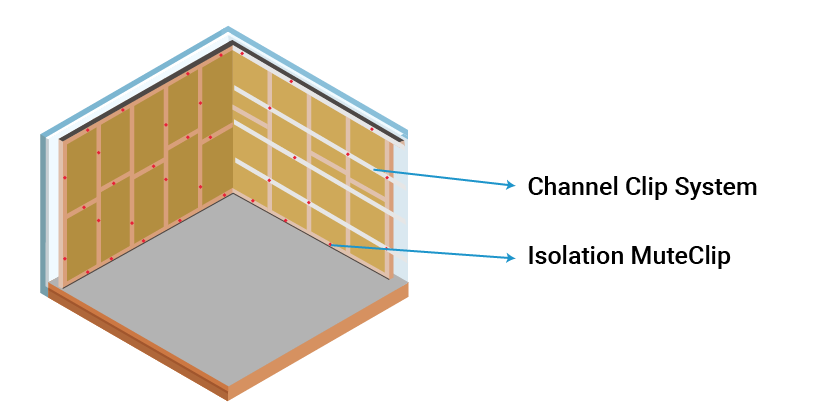

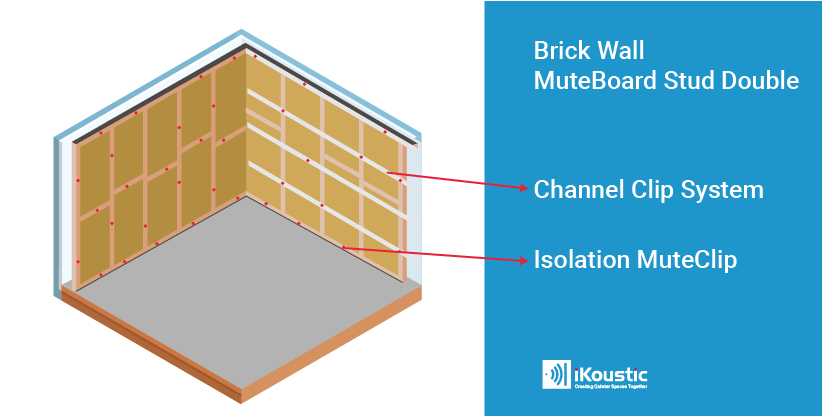

Step 3 – Install Isolation Clip and Channel

Mark out the location for MuteClips.

Screw isolation MuteClips to timber joists.

Clip channel into place.

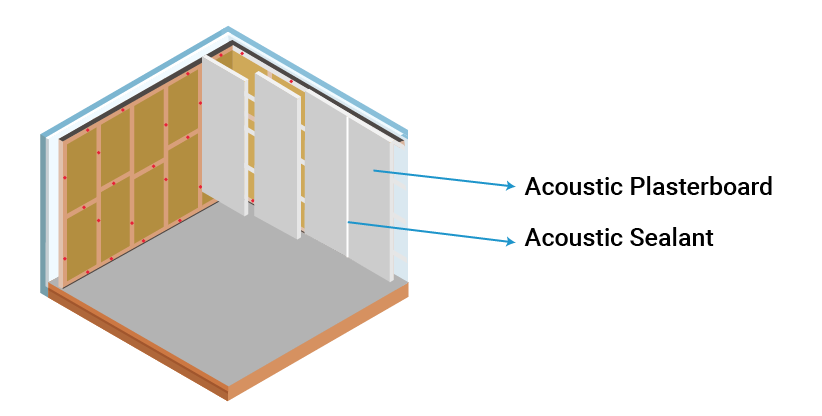

Step 4 – Mount Plasterboard

Measure out and score the soundproof plasterboard.

Using drywall screws, fix the board to the channels.

Seal gaps between the boards with acoustic sealant.

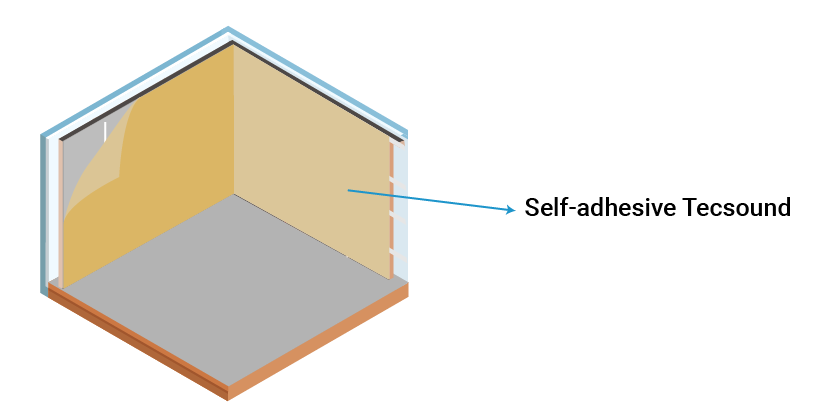

Step 5 – Install mass loaded vinyl

Peal backing off the Tecsound.

Adhere the mass loaded vinyl to the plasterboard.

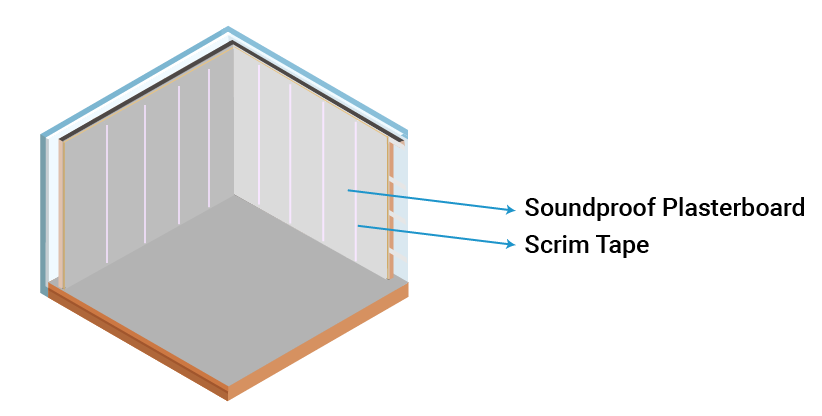

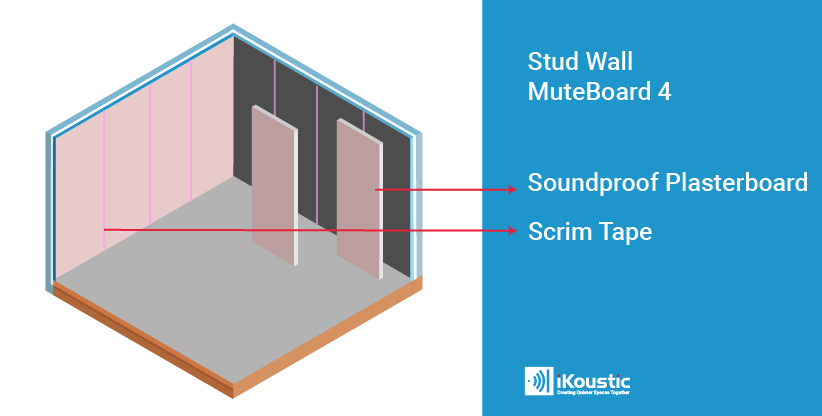

Step 6 – Add soundproofing plasterboard

Measure and score the second layer of soundproof plasterboard.

Screw the plasterboard to the wall, staggering the joins from layer one.

Seal the joins with acoustic sealant.

Tape over with scrim tape, ready for skimming.

Estimated Cost: 2600 GBP

Supply:

- MuteClip Isolation Clips

- MuteClip Chanel

- Acoustic Insulation

- Acoustic Plasterboard

- Mass Loaded Vinyl

- Isolation Strip F5

- Acoustic Sealant

- Applicator Gun

- Scrim Tape

- Gold Screws

- Self-Drilling Screws

- Dry Wall Screws

- Timber Stud Work

Tools:

- Saw

- Drilling Hammer

- Drill

- Spirit Level

- Step Ladder

- Stanley Knife

- PPE

Is there cheap wall soundproofing?

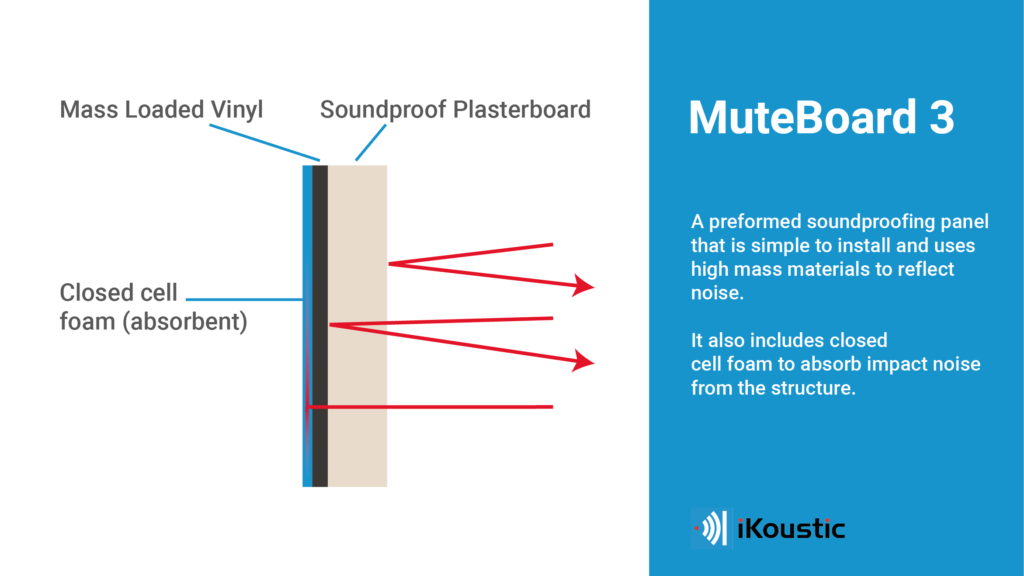

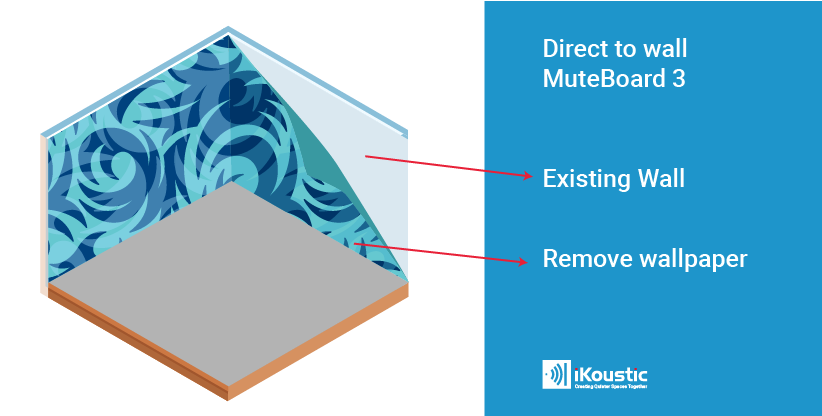

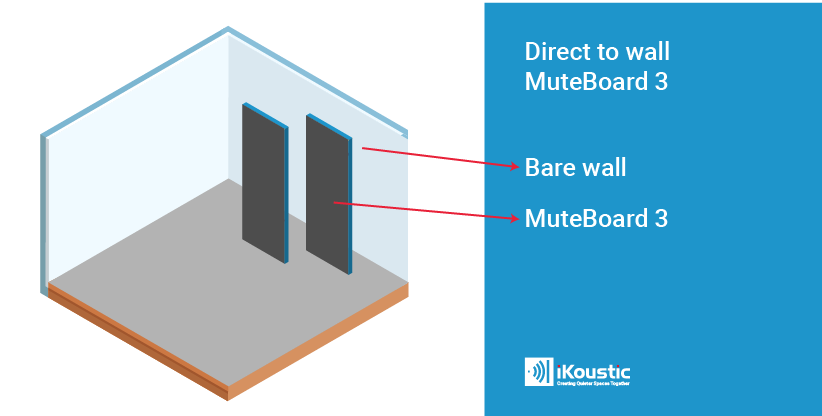

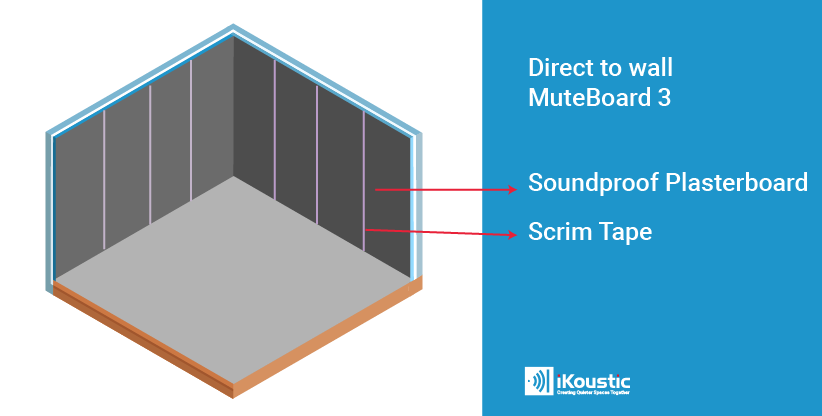

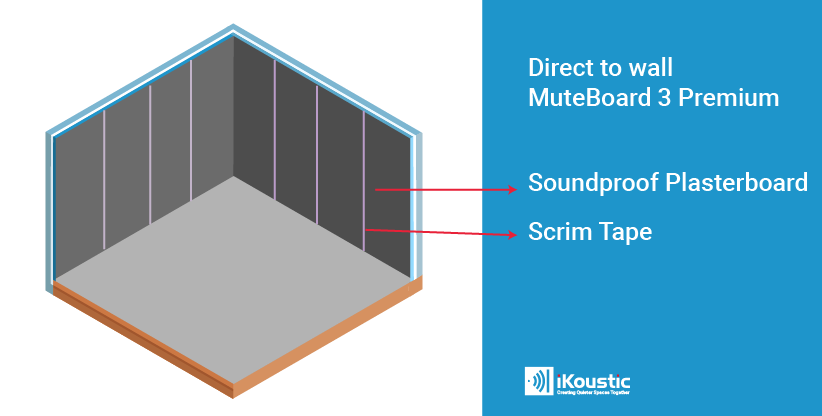

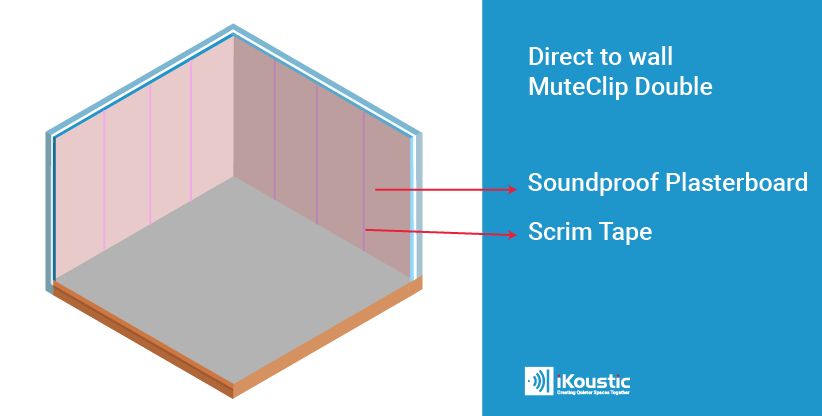

Yes, there is. Use a direct to wall method which will reduce your material and labor costs. Attach the soundproof panel MuteBoard 3 to the wall. This is a mix of mass loaded vinyl, closed cell foam and acoustic plasterboard to reduce airborne, impact and flanking issues.

MuteBoard 3 costs £41.60 per m2 as of 2023.

How much does it cost to soundproof a wall?

A direct to wall, cost effective solution can cost as little as £41.60 per m2. This involves using the MuteBoard 3 as a soundproof panel, mounted direct to the wall.

A full ‘room within a room’ independent wall soundproofing system costs around £74 per m2 as of 2023 but will yield superior results.

Does soundproofing a wall work?

Yes! There different soundproofing materials for different types of noise, different wall substrates and various budgets. Soundproofing a wall can reduce disturbance from noisy neighbours, loud traffic noise and sounds within the same building.

What is the best wall soundproofing?

The best way to soundproof a wall, is to use materials of high mass to insulate against airborne noise, use absorbent materials to reduce vibration transfer and absorb energy, and, utilize a decoupled structure to tackle low frequency noises like bass in music.

Can I soundproof a party wall?

Yes, it’s very common to soundproof a party wall against noisy neighbours. You must read and follow the Party Wall Agreement guidelines (explained fully here) and be sure to inform your neighbour. For best results use an independent wall soundproofing system.

Can I soundproof a wall without removing the drywall?

Yes! To soundproof without removing the existing plasterboard, use our direct to wall system. This is a cheap system that uses a soundproof panel made from acoustic plasterboard, mass loaded vinyl and closed cell foam. It will reduce both airborne and impact noise.

How to Soundproof a Wall Cheaply – Direct to wall

If you are looking for how to get cheap wall soundproofing, (full guide here then we have a simple and cost effective solution. We recommend a direct to wall solution, to keep your costs low and easily soundproof an existing wall. Direct to wall soundproofing is when we simply attach the materials straight to the wall without creating a decoupled structure and can be done without removing the drywall.

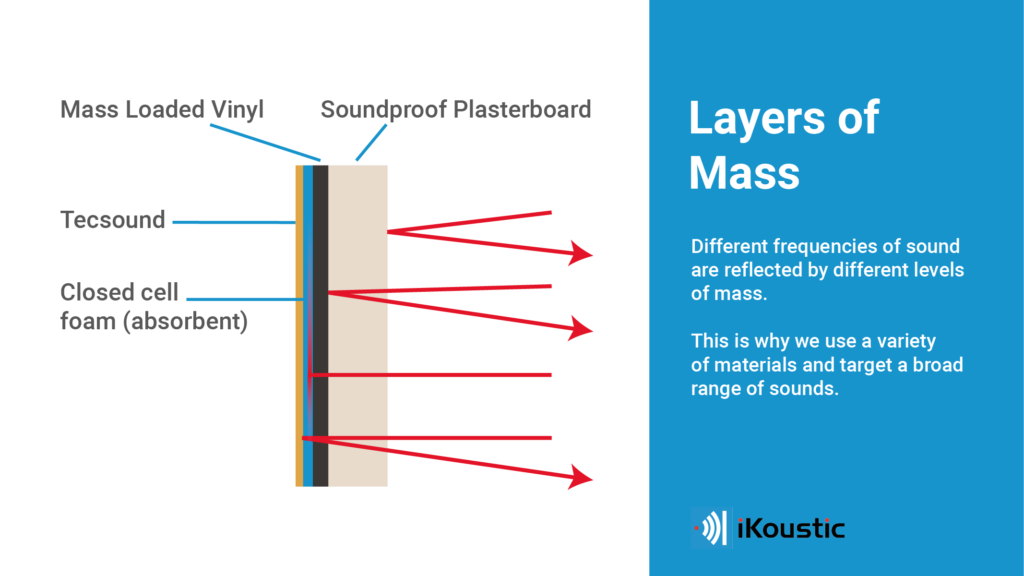

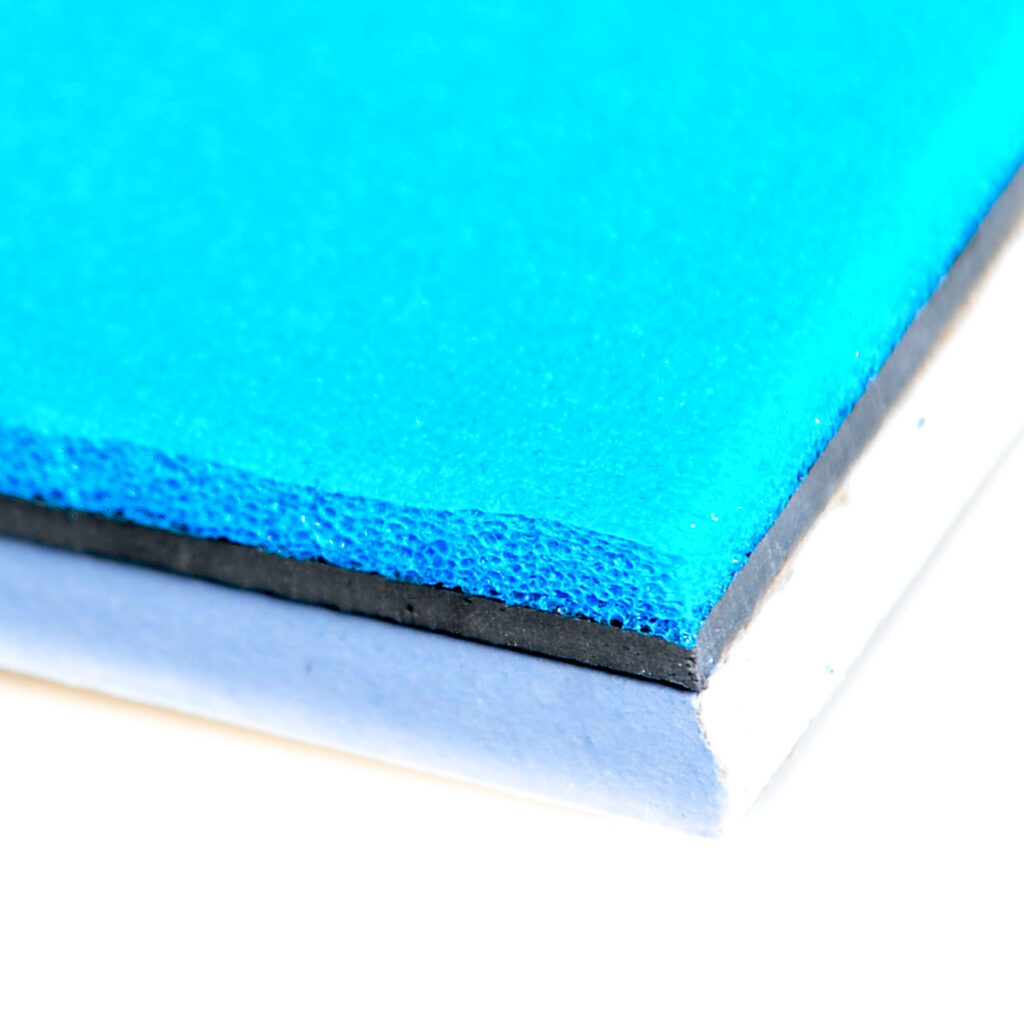

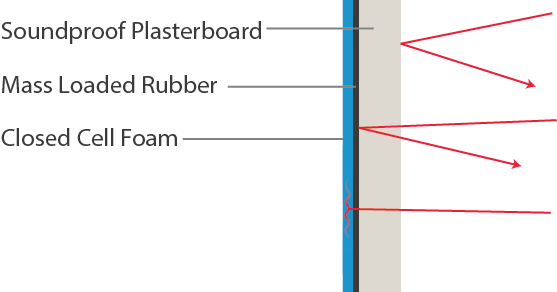

To soundproof a wall using this method, use MuteBoard 3 which is a ready made soundproof wall panel comprised of plasterboard, mass loaded vinyl and closed cell foam. The combination of these three materials gives you layers of different mass that can reflect a broader range of soundwaves. The closed cell foam will also help absorb sound vibrations that cannot be reflected, and convert the energy into heat. Below you can see how this direct to wall solution works.

Step 1 – Soundproof a wall cheaply – direct to wall

- If screwing to preexisting plaster, fill any holes and sand back.

- Unscrew socket boxes, ready for MuteBoard 3.

Step 2 – Soundproof a wall cheaply – direct to wall

- Measure your wall from floor to ceiling.

- Subtract 5mm from top, bottom and both sides.

Step 3 – Soundproof a wall cheaply – direct to wall

- Score and cut MuteBoard 3 to size.

Step 4 – Soundproof a wall cheaply – direct to wall

- Screw MuteBoard 3 direct to the wall.

- Ensure a 2-5mm gap remains between floor, ceiling and walls

- Fill the gaps with acoustic sealant and seal joints with scrim tape.

Soundproof party walls

We have a detailed blog for how to soundproof a party wall, but in essence it is the same as how to soundproof a wall. The only major difference is that you should be familiar with Party Wall Agreement and understand what you can and can’t do.

Usually, you’ll only be required to inform your neighbour of the work, however it is best to check and understand any limitations. We go through the ins and outs of the agreement in our dedicated blog on party walls.

DIY soundproofing walls from noisy neighbours

Many people soundproof a wall from noisy neighbours and need a DIY fix to keep labor costs down. Any of our systems to soundproof a wall can actually be installed by a confident DIYer! Some are more work intensive than others, but every system comes with detailed installation instructions to guide you.

Below we have ranked our best ways to DIY soundproof a wall from noisy neighbours by installation difficulty. Remember that if you need to soundproof against noisy neighbours but haven’t got the time or DIY prowess, we have an installer network ready to help you out.

| Soundproofing Wall System | DIYer Level |

|---|---|

| Direct to wall MuteBoard 3 | Basic |

| MuteBoard 3 Premium (for brick wall) | Basic |

| MuteBoard 4 Stud and MuteBoard 2 Stud (for brick wall) | Intermediate |

| MuteClip Brick Wall Systems: Single, Double, Stud Double | Advanced |

| MuteBoard 2 (for stud wall) | Basic |

| MuteBoard 4 (for stud wall) | Basic |

| MuteClip Double (for stud wall) | Intermediate |

How to reduce impact noise from neighbours

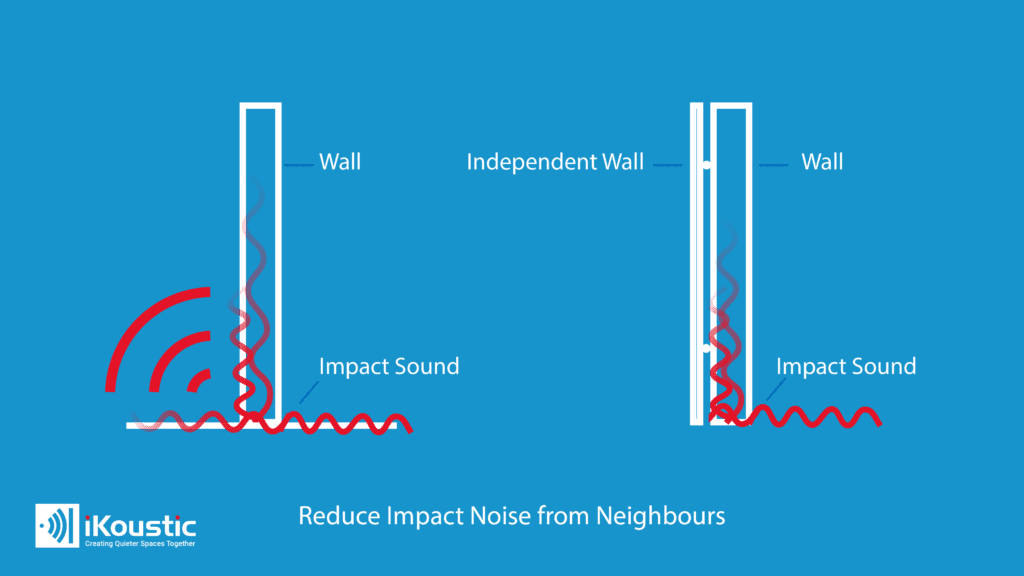

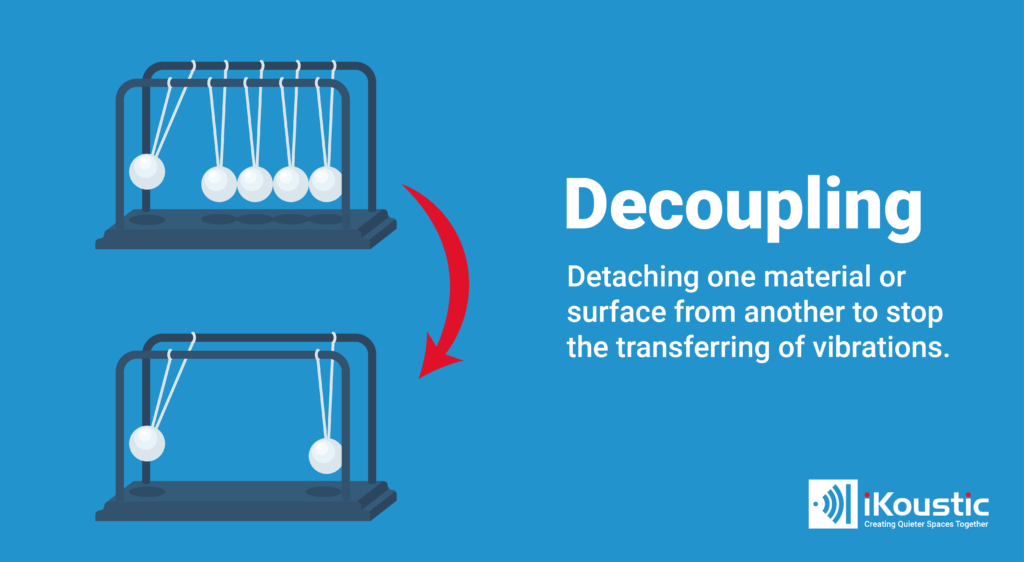

To reduce impact noise, you need to decouple structures. This is because impact noise, sometimes known as structure-borne noise, uses the house to travel through instead of the air. These vibrations pulse through your walls, floors, pipes – anything with a resonant frequency. An amusing example of how sound travels through a structure can be found in this clip from Gavin and Stacey.

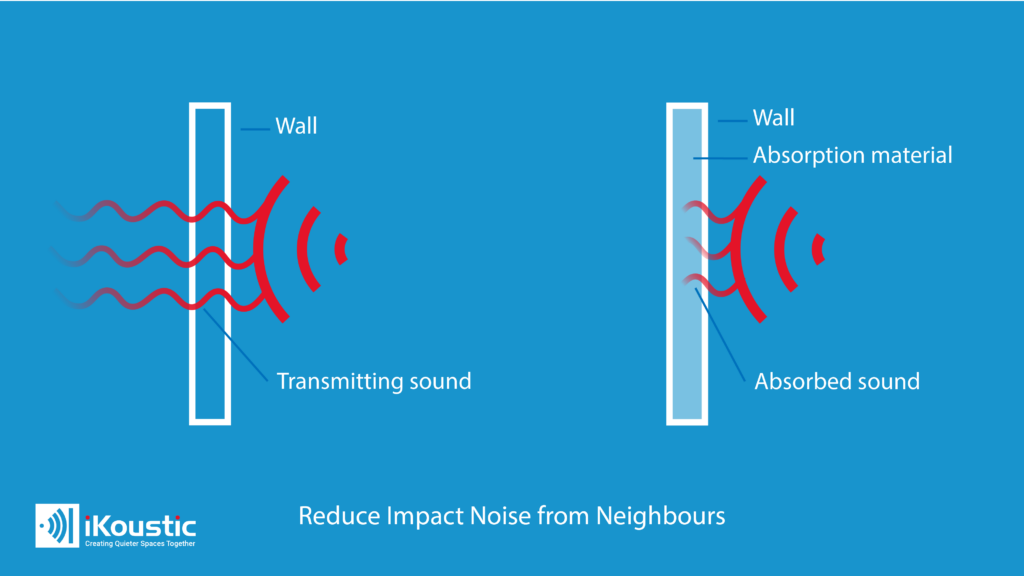

To reduce impact noise from neighbours, we need to create a physical gap between the structures. If this isn’t possible, then we use a variety of non-resonant materials to help absorb the sound energy and convert it into heat.

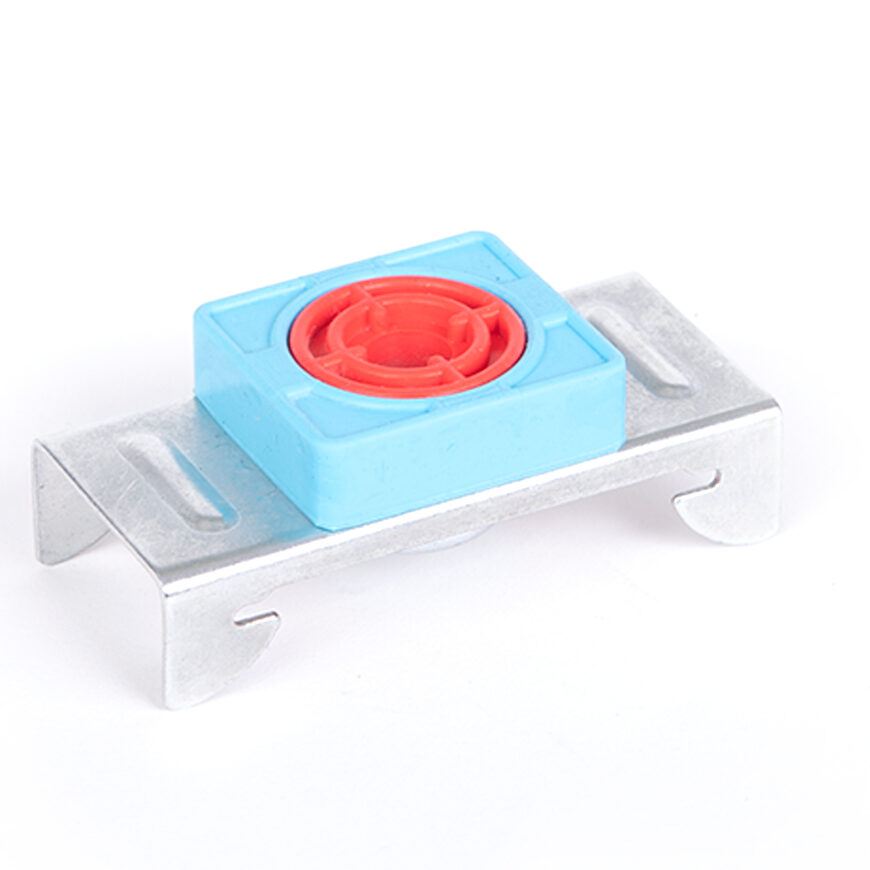

The best way to reduce impact noise form neighbours is by creating a ‘room within a room’ system. This would be an independent wall, and to soundproof a wall using this method we will install isolation clips. Isolation clips, or MuteClips, hold the new independent wall away from the existing structure, i.e your party wall.

By separating the two structures, we are able to soundproof a wall against impact noise transferring from one property into the next. If the MuteClip is out of your budget, then another option is to install a new timber stud frame and place the new timber on isolation strips. These are made from non-resonant rubber that is difficult to vibrate, even with high energy low frequency sounds.

How to reduce low frequency noise from neighbours

Are you experiencing low frequency noise from your neighbours like bass in music? Luckily, you can soundproof a wall against low frequency sounds and reclaim your quiet! Remember that if noise from your neighbours occurs between 11pm and 7am consistently, then you have ground to lodge a complaint with your local council under the Environmental Protection Act 1990. Low frequency sounds travel further than higher frequency sounds as they carry more sound energy.

While you can install absorbent materials against low frequency noise, it would take a lot of acoustic mineral wool to effectively damp low frequency noises! This is why we also use decoupled systems to help tackle lower frequencies, like bass music.

To soundproof a wall in this way, it is best to use a MuteClip isolation system. In installing this system, you will also need acoustic mineral wool absorption to reduce echoing between the existing wall and new decoupled structure. By also using a variety of high mass materials, you will build a comprehensive system that is able to tackle a variety of wave lengths.

Ultimately, though, the best way to reduce low frequency is by decoupling your walls as much as you are able! The system above shows a fully independent soundproof wall solution that will give you the best results.

What materials can block sound

In order to soundproof a wall, we employ a variety of materials, by why? Well, the first thing to understand is that there are two types of sound; airborne and impact (or structure-borne). These two types of soundwave require different approaches to soundproofing.

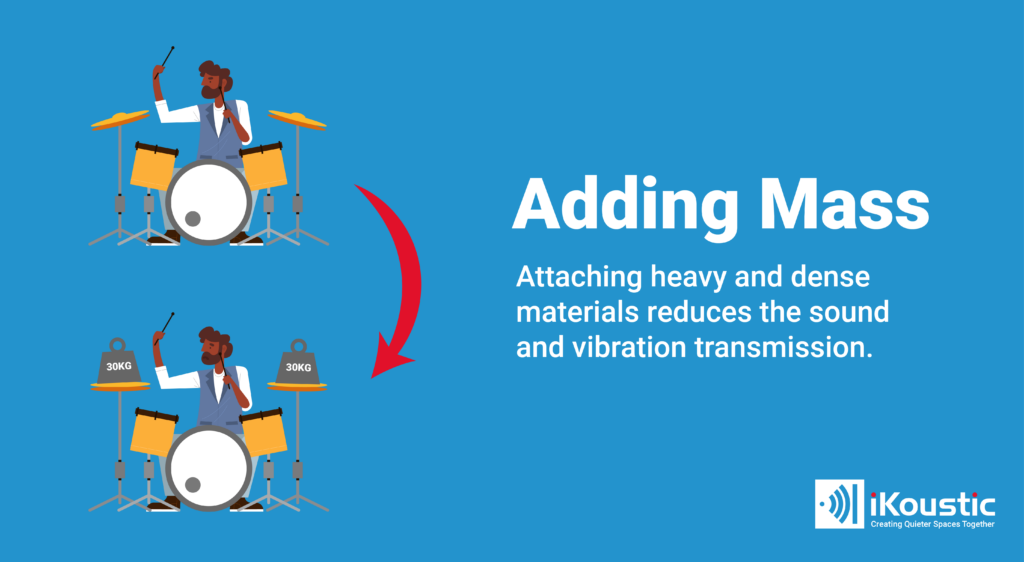

Materials of high mass are able to reflect airborne noise, specifically of mid to high frequency. This is because the airborne noise does not carry enough energy to make the material vibrate with the sound and transmit the energy into the wall. This is because high mass materials have a natural frequency (a frequency at which they naturally vibrate), that is low. Low frequencies require a greater amount of energy to be made, hence, a mid to high frequency hasn’t got enough energy to make the material transmit sound.

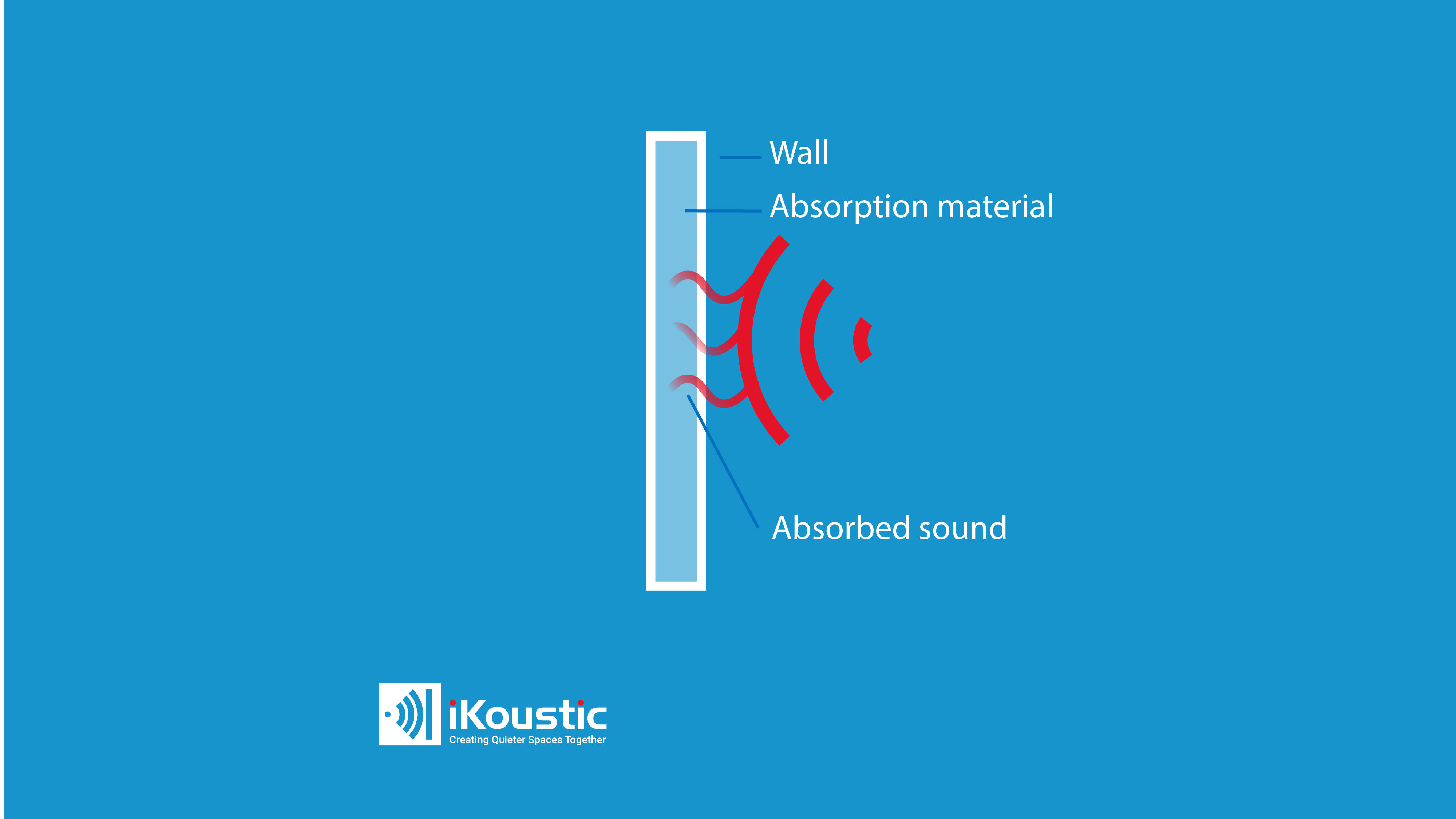

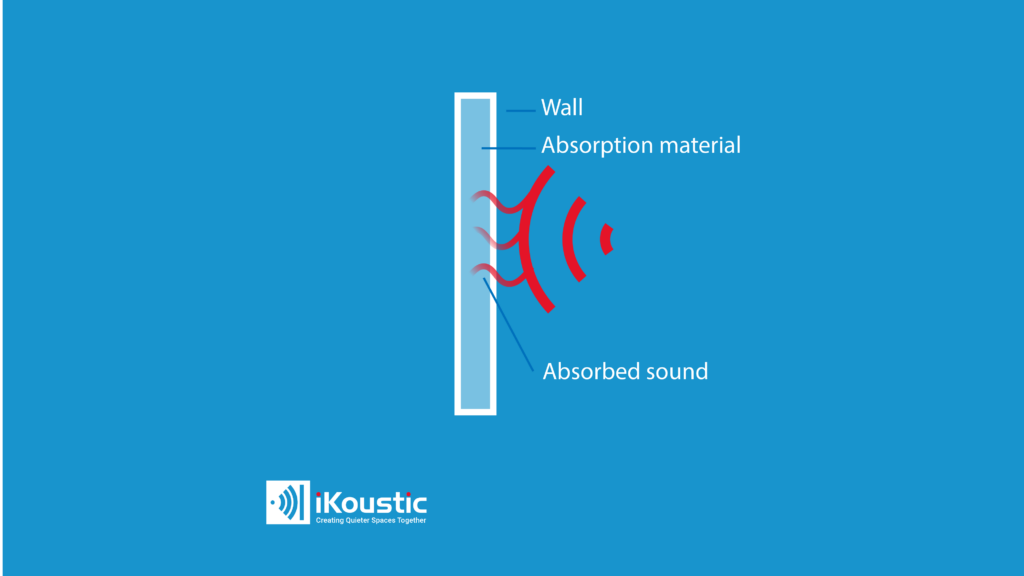

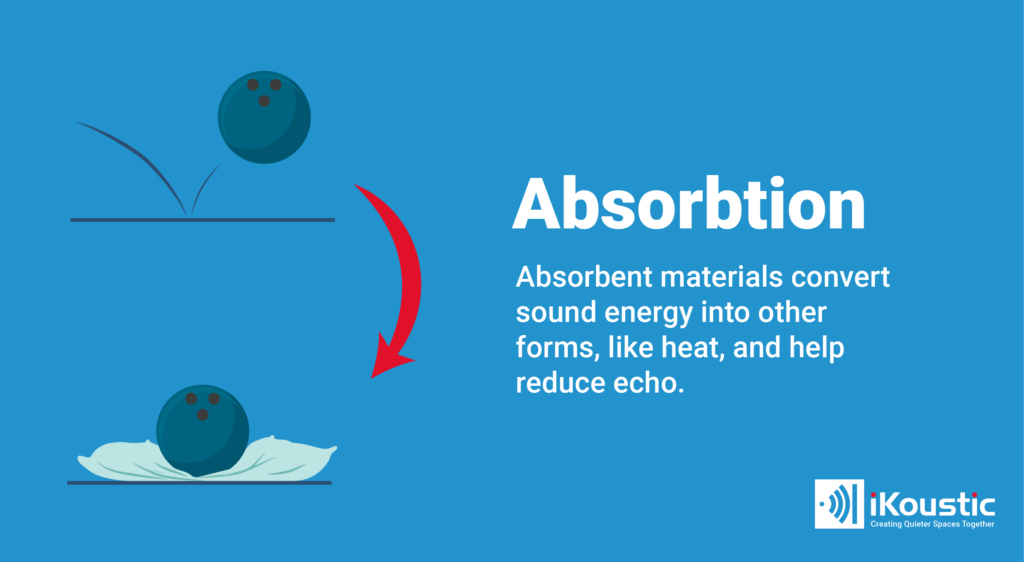

To combat impact noise, which is generated by two materials touching, we need a different approach. Impact noise travels through the structures of a wall, hence we need to ‘suck’ the sound energy out of the structure. We use absorbent materials to do this, as they don’t have a natural frequency and so the sound energy ‘exhausts’ itself by trying to make the material vibrate.

Lastly, materials which are non-resonant like our rubber crumb matting, are once again very hard to make vibrate with sound energy. This means that they help to ‘decouple’ structures when a physical space between them is not possible (such as walls resting on floor joist).

Sound Deadening

Sound deadening is a casual term that is used to describe how sound is treated within a space. Sound deadening is less about soundproofing against noise transmitting out of the room and more about the quality, or attenuation, of sound within the room.

When considering sound deadening material and how to soundproof a wall, this would involve using acoustic mineral wool for absorption. Absorbing the sound is a way to lessen the level of noise experienced inside a space. Unlike reflecting sound with high mass materials, absorbing sound takes it out of the space entirely and helps to ‘control’ the noise environment.

Sound deadening can also be achieved with additional treatment after installation of a soundproof wall. This would be in the form of acoustic panels or acoustic baffles which also help to absorb noise, or ‘sound deaden’.

Reduce echo in a room

When you soundproof a wall, you can reduce echo in a room. This is done by the same process as sound deadening, discussed above. Echo is created when sound is reflected off a surface, (and yes, this is how we soundproof against airborne noise transmitting through a wall!).

We need to absorb sound energy in order for it to stop reflecting off surfaces. Using materials like acoustic mineral wool, we can damp sound energy and convert it into heat energy. This works because absorption materials haven’t got a natural frequency at which they vibrate. Hence, the sound waves run out of energy as they try to vibrate the material.

When we soundproof a wall, we will add absorption into the wall itself. This is in the form a acoustic mineral wool which is fire resistant, moisture resistant and a class A absorption material! We have a range of acoustic mineral wools to choose form depending on your space, requirements and your budget.

Soundproof insulation for walls

To soundproof a wall by means of insulation actually means to add material of high mass. Most people may assume insulation refers to acoustic mineral wool, as it looks like regular loft insulation, but this is actually sound absorption.

Soundproof insulation for walls takes the form of high mass materials, such as mass loaded vinyl’s, soundproof plasterboard and visco-elastic membranes. These all work by reflecting sound and preventing it escaping the room. Insulation is less to do with sound inside the room and all about sound escaping the space. This is especially important for spaces like drumming sheds and home cinemas.

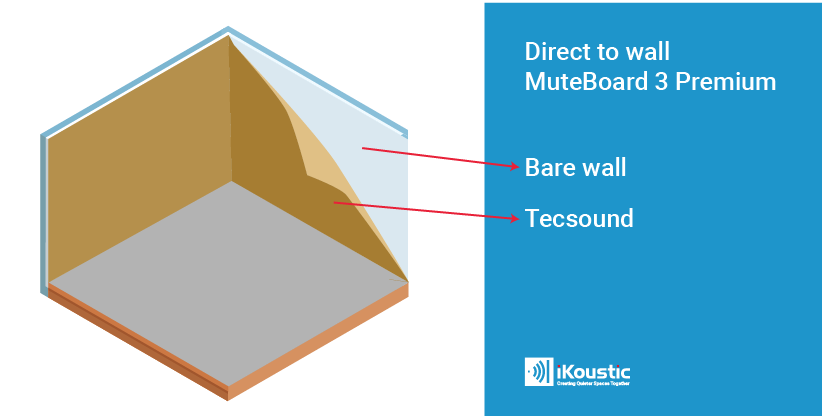

The best materials to sound proof a wall by means of insulation would be those materials with the highest mass. We would always use soundproofing plasterboard, then a mass loaded vinyl or visco-elastic membrane – or both! Below is a cross section from our MuteBoard 3 Premium system and it also includes closed cell foam to help absorb sound and prevent echo between the layers.

Soundproof Wall Paneling

Undoubtedly, to soundproof a wall we need to look into the best soundproof wall paneling for the job. Here, you have a variety of options, all of which will be best depending on the space available, your budget and noise requirements.

Soundproof wall paneling is usually a high mass material to help reflect sound back into a space. However, here at iKoustic we have modified soundproof panels to include absorption as well! This means that your soundproofing wall panels can work much harder for you and, as they are preformed, the installation is much simpler, too.

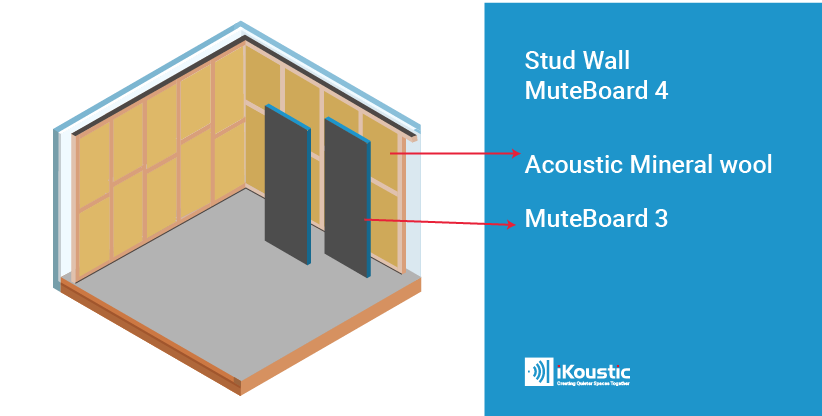

The best soundproof wall paneling

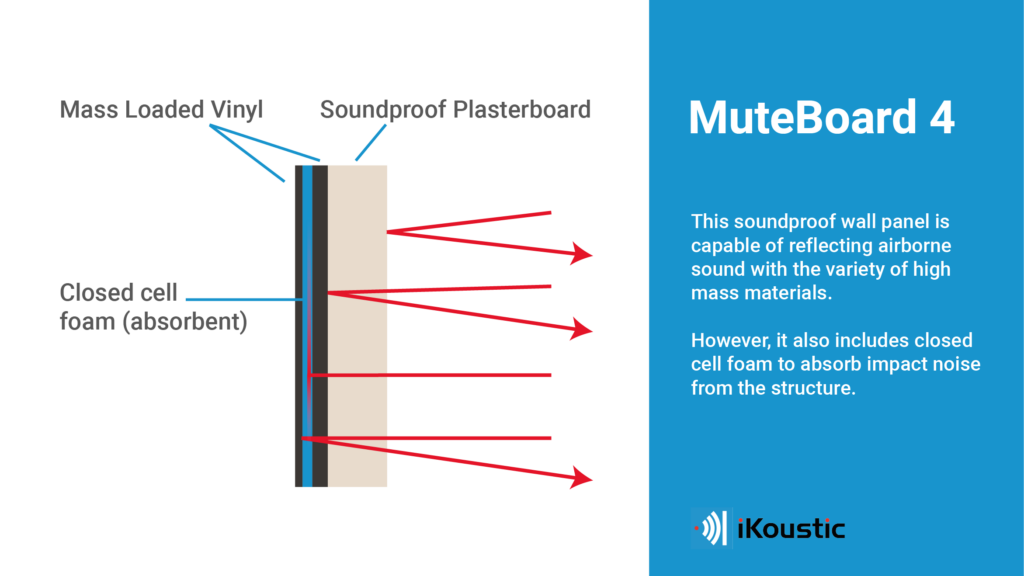

Our best soundproof panels for a wall would be the MuteBoard 4. This is a a brilliant mix of soundproof plasterboard, backed with a layer of high mass vinyl, followed by a section of closed cell foam and finished with another layer of mass loaded vinyl but at a different mass.

The plasterboard for soundproofing has a high mass and makes the system ready to skim over for a quick finish. The soundproof plasterboard has a higher mass than regular plasterboard and also offers rigidity to the system.

Cheapest soundproof wall paneling

If you’re on the budget tour when it comes to how to soundproof a wall, then we have you covered. The most cost effective soundproof wall paneling is our MuteBoard 3. You will notice that the MuteBoard 2 is slightly cheaper, however, this is designed to be used as part of system. By itself the MuteBoard 2 would not be recommended, save you cash and do it well!

The MuteBoard 3 is ideal when you need to soundproof a wall cheaply as it uses three distinct layers. Similar to the MuteBoard 4, this soundproof panel uses acoustic plasterboard, mass loaded vinyl and closed cell foam. Unlike the previous soundproofing panel, MuteBoard 3 does not include the extra mass loaded vinyl layers, hence a lower price!

This soundproofing wall panel is still effective when it comes both types of sound and will give you a great improvement on your current noise situation.

Plasterboard for Soundproofing

You will have likely heard of soundproof plasterboard and might wonder what enables it to soundproof. Well, compared to ordinary plasterboard, plasterboard for soundproofing has a higher mass. As we already know, materials with more mass are much harder to vibrate. This means that more sound energy must make contact with the wall in order for it to allow sound to transmit.

When we soundproof a wall, it’s always a good idea to incorporate a mix of soundproofing materials. This means that we can reflect a range of sound frequencies, incase one of the frequencies is able to pass through layer one, or even layer two.

Like most materials, plasterboard for soundproofing has a resonate frequency but it’s fairly low. Even so, being that it has the ability to vibrate with sound energy, here at iKoustic we back plasterboard with other high mass materials. These form our MuteBoard range which make installing multiple layers quick and simple. The soundproof plasterboard adds important rigidity to the structure and holds up the mass loaded vinyl’s as well as closed cell foam or even visco-elastic membranes like Tecsound.

Plasterboard for soundproofing is also useful as, with the addition of scrim tape, it is ready for a skim layer! This makes the whole process of soundproofing a wall much more straight forwards. We also offer soundproof plasterboard in half board sizes, making it easier to deliver and install, especially if you plan to DIY your soundproof wall.

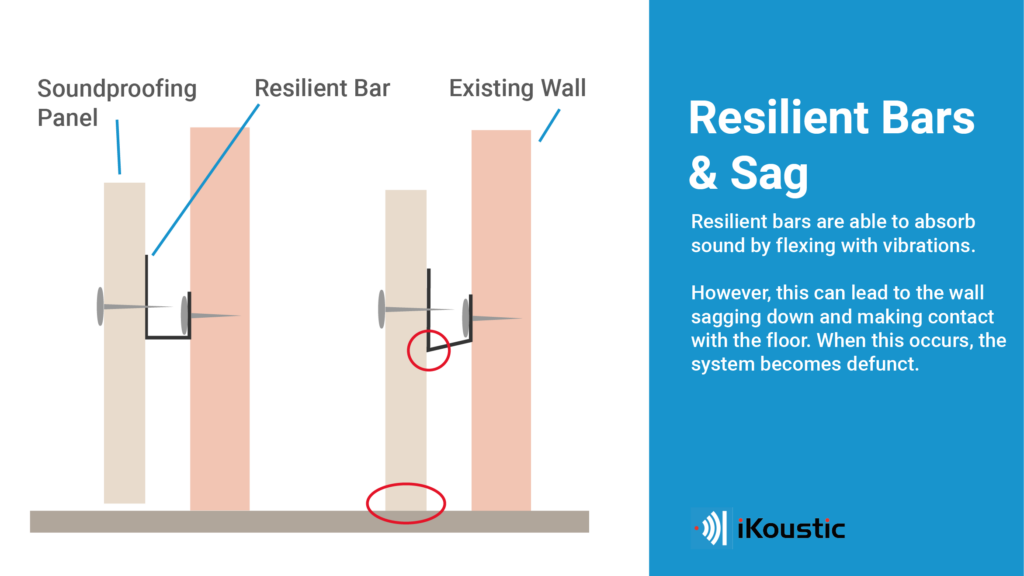

Resilient Bar wall soundproofing

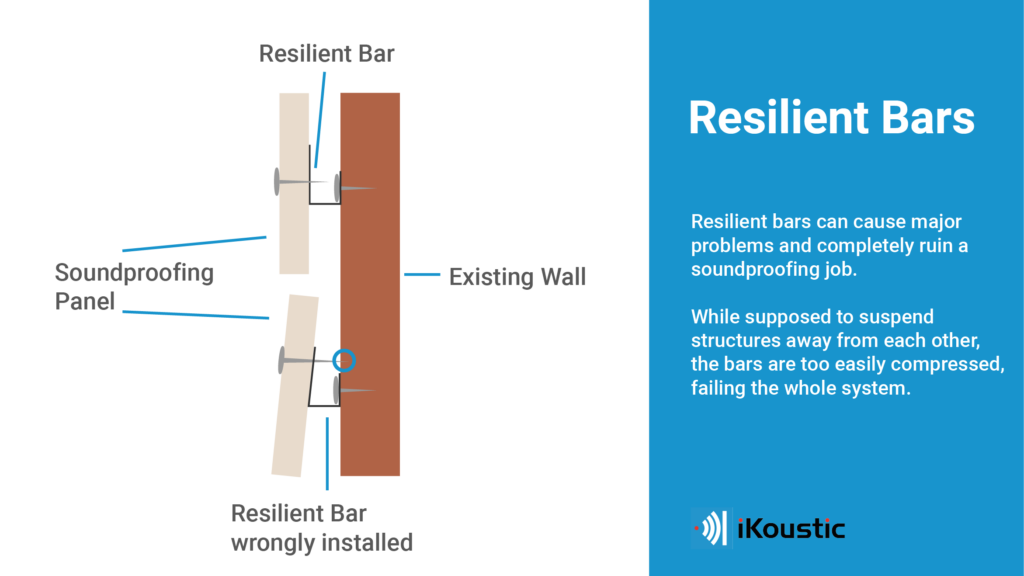

To soundproof a wall with decoupled systems, we look ‘hover’ the wall away from the existing structure. Many people have heard of resilient bars, however, we don’t recommend using them! We used to sell resilient bars, but upon discovering how easily they can ruin a soundproof wall, we no longer advised their installation.

The main issue with resilient bars is that the system is far too easy compressed with either too much pressure on installation, or, the wrong screws. This short circuits the decoupled wall and you will loose your soundproofing benefits! While resilient bars may appear cheap, they end up costing far more in the long run when a soundproofing system has to be taken apart. We have seen it happen many a time!

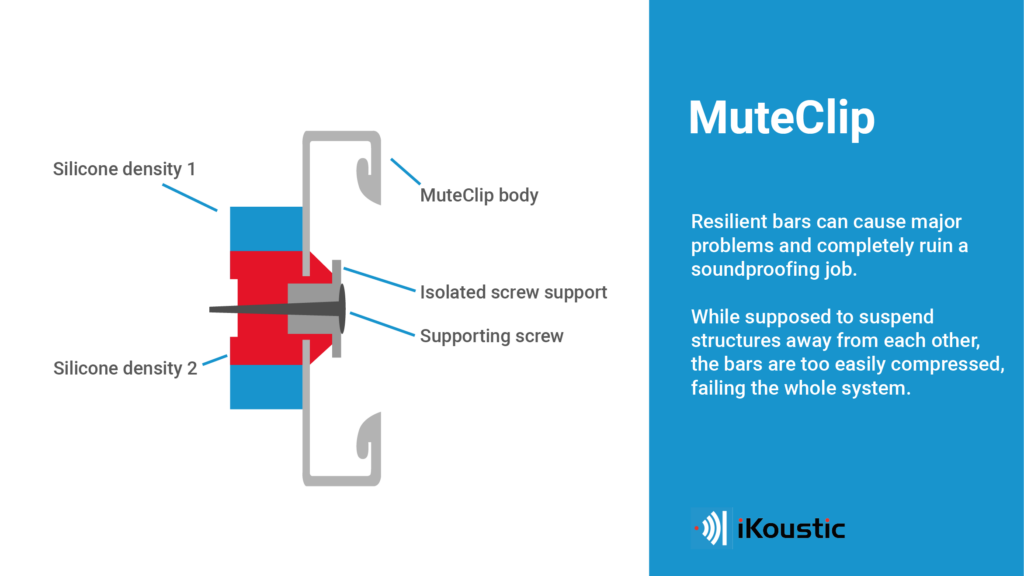

Furthermore, when you soundproof a wall, you want to try and use a variety of methods and while a resilient bar offers isolation, it only provides this in one way. The resilient bar is made of metal which can vibrate and actually allow the sound to be isolated within the bar. However, using a silicone, like the isolation clips do, will isolate sound far more efficiently and effectively. It also means that the metal clip which is supporting the wall is not in direct contact with the source of the sound.

We knew that a resilient bar could work so much better with some adjustments and so we set out creating an isolation system that could be used to properly soundproof a wall.

Resilient bar common issues

Besides the installation problems that often occur when installing resilient bars to soundproof a wall, the system can fail later on. Resilient bars work by allowing a certain amount of flex in the bar. This is to ensure that sound vibrations are isolated and quietened.

However. While resilient bars might seem like the best way to soundproof a wall through isolation, they can fail you further down the line. The flex in the metal resilient bar can cause the independent soundproof wall to sag over time. This sagging eventually results in the soundproof wall panels touching the floor.

When the soundproof wall panels make contact with the floor, the whole system is no longer independent and, therefore, does not isolate the sound. Instead, the sound can move through the wall, to the floor and back up to the soundproof panels. This is known as flanking, when sound finds a different passage to the other side of a structure.

Soundproof a wall with isolated systems

The best isolated systems truly decouple materials and make a huge different when it comes to the transmission of impact and low frequency noise. Being that a resilient bar fails too easily, we designed a better isolated system in the form of the MuteClip and channel. We ended up designing a full range so that ceilings, floors and walls can all benefit which then creates the ‘room within a room’ solution.

For our isolated floating wall, an isolation clip is your top option and will give you the best soundproofing results by far. Remember that resilient bars allowed sound to travel along the metal? Well we solved this issue with our unique MuteClip design by using dual density silicone buffers.

The MuteClip offers a far better resistance to the passage of sound and truly isolates your walls. To soundproof a wall with MuteClips, we first need to decide on a soundproofing system and can then design the installation. All of our systems come with installation guides if you plan to soundproof a wall by yourself. Equally, we have an installer network ready and waiting to help you soundproof a wall.

How to soundproof a brick wall

Often, you’ll find that you have a solid party wall, or brick wall. This is great for soundproofing as brick already has a high mass and so you’ll be able to achieve results a little more easily. You are able to install a direct to wall soundproof panel without needing acoustic insulation behind it.

Of course, as with any direct to wall soundproofing panels, these are the starting point for results. To start improving on them, we will add more materials. It can be a good idea to use a visco-elastic membrane with brick work as this helps to damp sound and reduce the reverb which can result from too many hard surfaces.

Of course, if you have many hard surfaces besides your brick walls, you could also look at acoustic wall panels to moderate the acoustics inside the space. We will look further into this later on in the post.

Soundproof a wall with direct to wall panels

For brick work, we have to two systems that are tried and tested for a direct to wall panel solution that doesn’t involve stud work or isolation systems. One is a cheaper option and the other slightly dearer with a little more work involved, too.

Easy way to soundproof a wall

First up, we have the direct to wall soundproof panel which is the only material used to soundproof a wall with this system. It keeps things easy! The MuteBoard 3, our trusted soundproofing panel, is making another appearance. It comprises of a layer of soundproofing plasterboard, high mass vinyl and a layer of closed cell foam.

This can be easily screwed into your existing wall for an immediate improvement on your noise issues. This is an easy and simple fix for noisy neighbours and can be installed in a weekend. Find out more about soundproof panels here.

Materials needed to soundproof a wall

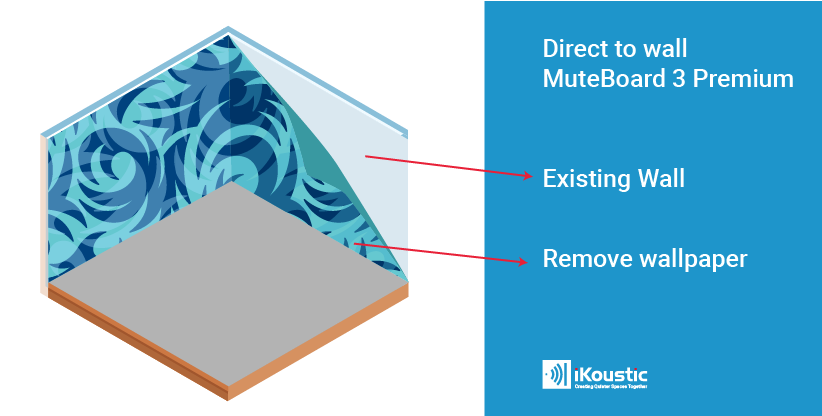

Step 1 – Remove wallpaper and prepare surface

- Remove any wall paper

- Fill holes and cracks in the wall (these would let in sound)

- Ensure the surface is clean and dry

Step 2 – Cut Soundproof Panels and Install

- Measure your wall to be soundproofed

- Score and cut the MuteBoard 3 panels to size

- Install the panels with raw plugs

Step 3 – Finish the soundproof wall

- Fill gaps between soundproof panels with acoustic sealant

- Fill the 2-5mm perimeter gaps with acoustic sealant

- Finish joins with scrim tape ready for a skim plaster finish

Easy install brick wall soundproofing

Another method is to use one extra material. This is slightly more expensive but will improve your performance by 2 dB. While 2dB might not sound like a lot, sound is measured on a logarithmic scale. A logarithmic scale, in this case the decibel scale, is when measurements are compressed as the value range is so large. This actually means that for every 1dB increase, the increase is actually by a factor of 10!

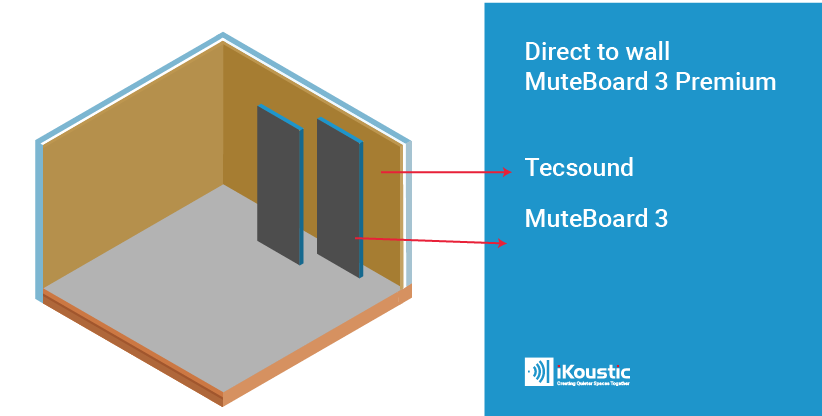

For this system, we are choosing the MuteBoard 3 Premium which includes a layer of visco-elastic membrane, Tecsound. Tecsound is able to reduce both impact and airborne noise. Here, it will be reducing airborne noise and also damping flanking that may try to travel up or down the wall.

Materials you’ll need to soundproof a wall

Step 1 – DIY soundproof walls

- Begin by removing any wallpaper

- Fill holes and cracks in the wall and sand smooth

- The wall should be clean and dry before beginning

Step 2 – DIY soundproof walls

- Cut Tecsound visco-elastic vinyl to size

- Adhere to wall using self-adhesive backing

Step 3 – DIY soundproof walls

- Measure wall to be soundproofed

- Cut the MuteBoard 3 soundproofing wall panel to size

- Screw into the existing wall securely

Step 4 – DIY soundproof walls

- Fills gaps and edges with acoustic sealant

- Tape up joints with scrim tape ready for your final finish

How to soundproof a wall with an independent structure

If you are looking for a high lvel of soundproofing, then you’ll be needing a decoupled structure. These are the systems that use MuteClips to hold the new layer of soundproof panels away from the wall. To soundproof a wall with MuteClips, you should ocnsult the official installation guide to properly measure out the design. If you need help with this, our technical team are always on hand so give them a call.

We are going to look at our most advanced system to soundproof a wall; the MuteClip double stud. This involves building an independent stud frame that is built 5mm away from the existing wall to isolate sound and decouple structures. Over this we use out MuteClip system to suspend three layers of soundproofing panels. Let’s see how to soundproof a wall using this independent wall method…

Supplies needed to soundproof a wall

- Isolation F5

- Acoustic Mineral Wool

- MuteClip

- MuteClip Channel

- Soundproofing Plasterboard

- Tecsound

- Acoustic Sealant

- Scrim Tape

Step 1 – Building a soundproof wall system

- Measure and cut your stud frame to size.

- Assemble the stud frame wall and apply isolation trip PF to the sides.

- Install the stud frame work, ensuring it is 5mm away from the existing parallel wall.

Step 2 – Building a soundproof wall system

- Install acoustic mineral wall between the joists to prevent echo.

- This should be a snug fit

Step 3 – Building a soundproof wall system

- Use the detailed installation guide to mark out locations for the MuteClips.

- Screw MuteClips to the wall.

- Clip channels securely into place.

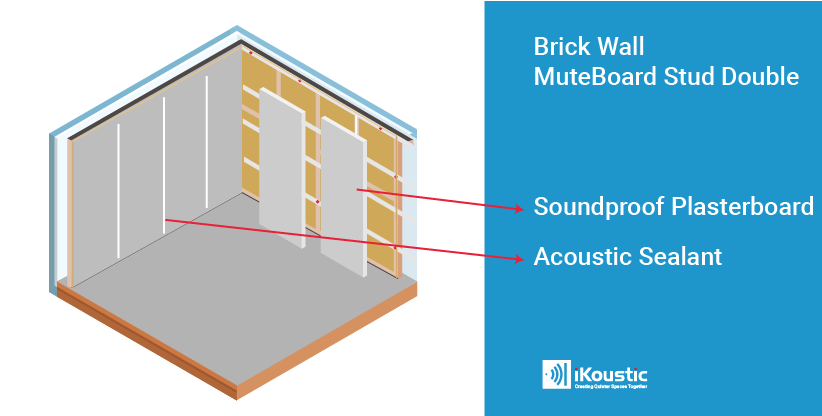

Step 4 – Building a soundproof wall system

- Measure and cut the acoustic plasterboard to size.

- Install the plasterboard by screwing it into the channels, leave a 5mm gap around the perimeter.

- Apply acoustic sealant to the gaps between each panel and around the edge.

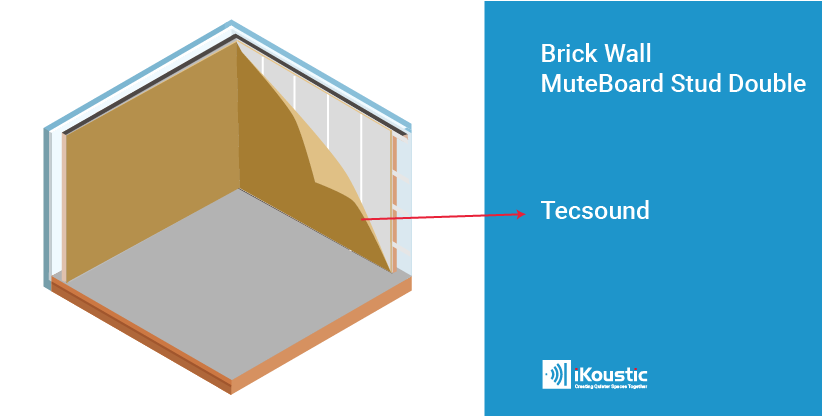

Step 5 – Building a soundproof wall system

- Measure and cut the Tecsound to the correct size.

- Roll onto the wall using the self-adhesive backing to stick.

Step 6 – Building a soundproof wall system

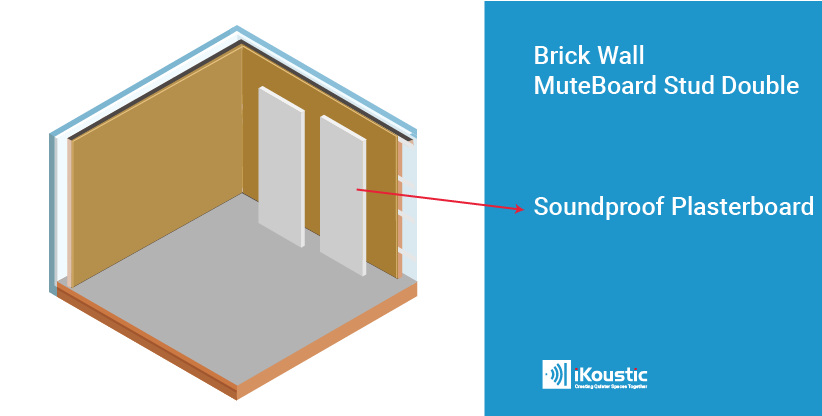

- Once again measure and cut your soundproofing plasterboard to size.

- Be sure to stagger the joins from the first layer.

- Screw into place.

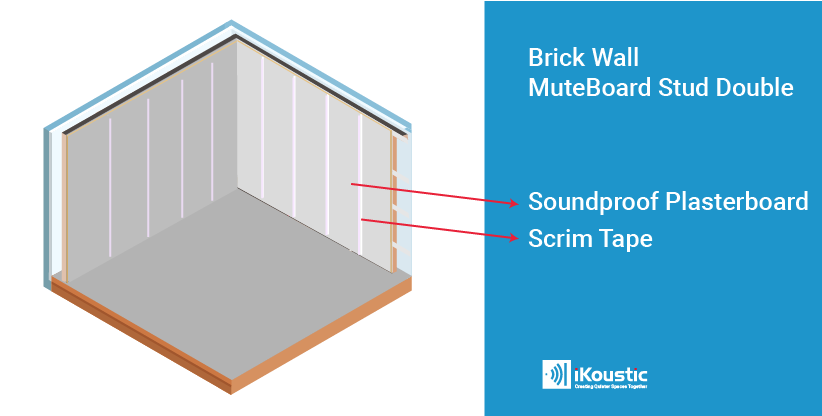

Step 7 – Building a soundproof wall system

- Finish your wall with acoustic sealant between the gaps.

- Seal the soundproof plasterboard joints with scrim tape.

- You are ready to skim finish!

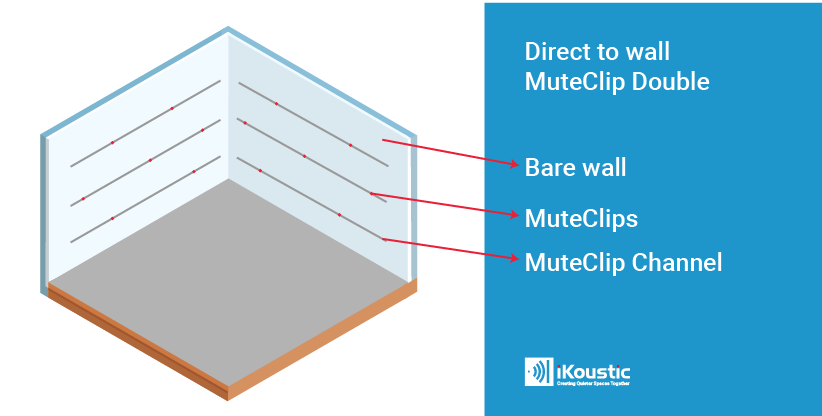

No framework isolation wall soundproofing

If you aren’t quite confident to DIY soundproof a wall, then there are decoupling options that don’t involve a stud frame. This significantly reduces the DIY involved and makes soundproofing your wall much easier! Let’s take a look at how the MuteClip Double for a brick wall can be installed.

What you need to soundproof a wall

- Acoustic Mineral Wool

- MuteClip

- MuteClip Channel

- Soundproofing Plasterboard

- Tecsound

- Acoustic Sealant

- Scrim Tape

Step 1 – Isolation system wall soundproofing

- Use the installation guide for MuteClips to mark out clip positions.

- Screw isolation clips to the brick wall.

- Clip channel into place.

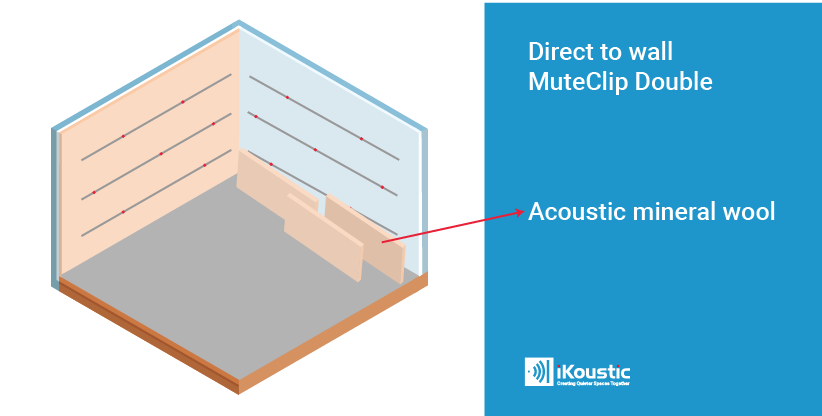

Step 2 – Isolation system wall soundproofing

- Install acoustic mineral wool between the channels.

- This should be a snug fit.

Step 3 – Isolation system wall soundproofing

- Install acoustic mineral wool between the channels.

- This should be a snug fit.

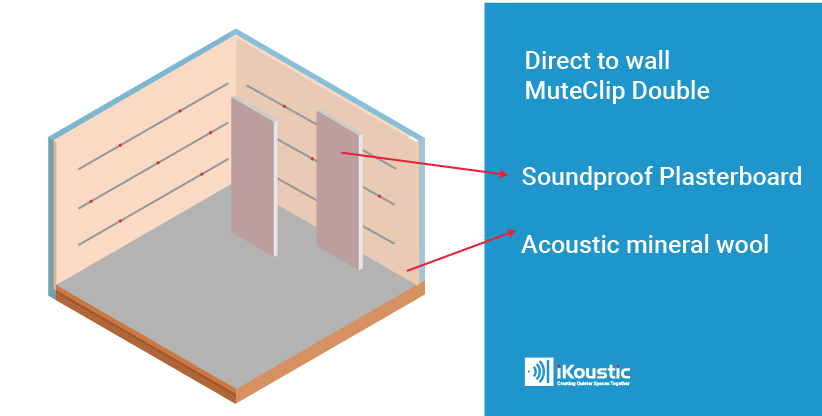

Step 4 – Isolation system wall soundproofing

- Seal the soundproof plasterboard board joints

- Roll the self adhesive Tecsound over the plasterboard.

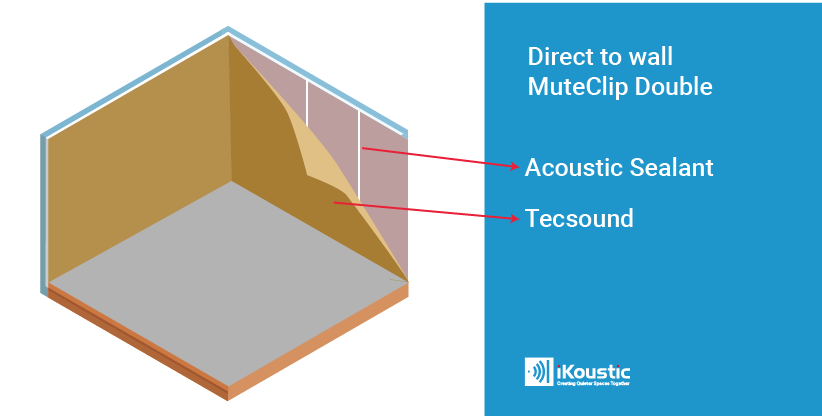

Step 5 – Isolation system wall soundproofing

- Cut and install the second layer of soundproof plasterboard.

- Fill all of the gaps with acoustic sealant and then cover with scrim tape.

Soundproof a wall – extra systems

If none of the above fit the bill for you, then we have a few other systems to soundproof a wall. The extra three options below are variations on the systems already explored in this post. MuteBoard 2 Stud is the only curve ball and introduces a new product that’s a composition of soundproof plasterboard and Tecsound.

Because these products are already fitted together, it makes installation much easier and you’ll soundproof a wall in no time! Note that we have coupled this with a acoustically insulated stud frame. This is key, as, by itself MuteBoard 2 wouldn’t be effective enough in most situations.

Below we have a full table to help you decide which system is best for you specific needs.

[wpdatatable id=6]

Soundproof Stud Wall

If you haven’t got a brick wall to soundproof and need a stud alternative, then worry not as we have options for you, too! Being that a stud wall has less mass, to achieve the highest soundproofing standards we need to use the very best systems.

What do I need to soundproof my wall?

Step 1 – Install soundproofing wall panels

- If you are installing a second, or new, stud wall, stick isolation F5 to the edges.

Step 2 – Install soundproofing wall panels

- Fit acoustic mineral wool in between the wood joist work.

Step 3 – Install soundproofing wall panels

- Cut and fit the MuteBoard 4 soundproofing panels to the wall.

Step 4 – Install soundproofing wall panels

- Cut and fit the soundproof plasterboard to size.

- Screw into the timber stud wall.

- Finish with acoustic sealant and scrim tape ready for your final finish.

How to install MuteBoard 2 stud wall soundproofing

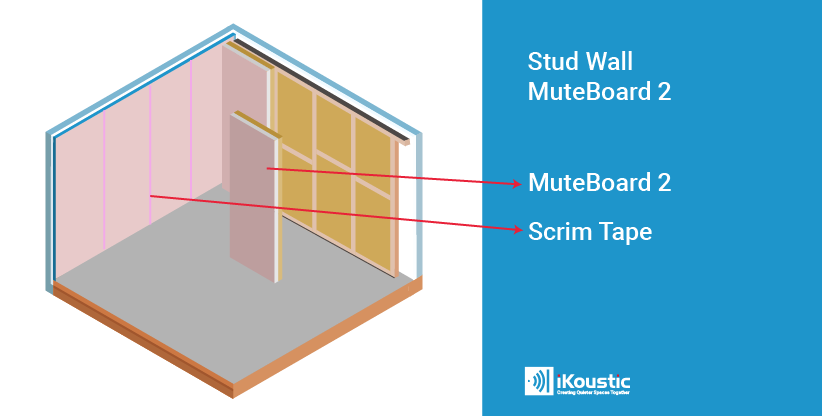

Another good option to soundproof a wall is the simple MuteBoard 2 system. This is a precomposed soundproof plasterboard stuck to the visco-elastic Tecsound which helps reduce airborne noise even further.

Because the soundproofing wall panel is in one piece, it makes installation far easier and faster! You can attach this to a preexisting stud frame, or, to a new stud frame if you want to increase the soundproofing qualities.

Soundproof materials for a wall

Step 1 – How to soundproof a stud wall

- If you are creating a new stud frame, then adhere isolation strip F5 to the perimeter.

Step 2 – How to soundproof a stud wall

- Snuggly fit acoustic mineral wool between the wooden joists.

Step 3 – How to soundproof a stud wall

- Measure and cut the MuteBoard 2 to size.

- Indstall the soundproofing panels with dry wall screws.

The best stud wall soundproofing

If you are looking for the best way to soundproof a wall and haven’t got the upper hand of brick work, then it’s time for our showstopper solution. This involves the MuteClip, of course, and will be a major upgrade to the soundproofing quality. The MuteClip stud double provides high mass, with varying densities, and a fully decoupled solution to tackle the most pertinent of low frequency noises.

To soundproof a wall with this system, firstly consider the space it will take up and how much you are willing to loose. If you are able to loose even more, then you could even erect a second independent stud timber frame 5mm away from the existing wall. This is going to add one more layer of defense between you and your noisy neighbors.

How much to soundproof a wall? (2023 prices)

Depending on the system you choose will vary your price. However, the cheapest (while still effective!), way to soundproof a wall is going to cost in the region of £41 per m2. If you were to upgrade to a full independent wall system, your costs are looking at around £74 per m2. This would be for all of your specialist soundproofing materials but not for the extra timber needed for stud work.

Soundproofing Installers

If you aren’t looking for a new DIY project, then worry not. Here at iKoustic we have a fabulous network of soundproofing installers. These specialists know how to soundproof a wall like the back of their hand and will deliver you the best results. Competent DIYer’s may enjoy the challenge in learning how to soundproof a wall, however, if you aren’t so thrilled by the prospect then find a soundproofing expert today!

Pass Part E Wall Soundproofing

If you need to meet Part E soundproofing then worry not as some of the systems already mentioned will get you there! Part E are a set of regulations and restrictions passed by the Government in 2003. The document goes into depth on many aspects of soundproofing, including floors and ceilings, too.

Here at iKoustic, we are specialised in helping material change of use projects meet the requirements. This primarily concerns the conversion of a house into flats. Part E is all about the resistance to the pass of sound and keeping it to an acceptable level. If you want to know more about Part E, you can read this blog here.